Solder Paste Types

There are a wide variety of solder pastes available in the market that can be used for diverse applications.

Every application requires a certain paste, as each has its own strengths and weaknesses.

Lead-Free vs. Leaded

Which solder paste is best for your process?

Read on to find the solution

Lead-Free Solder Paste

Regulations made by the Restriction of Hazardous Substances (RoHS) require some products to be manufactured with lead-free solder paste. As lead pollution in landfills increases, this regulation is part of the effort to implement sustainable manufacturing practices. As humans and technology grow even closer, it’s of the utmost importance that we not only keep hazardous chemicals away from our landfills, but away from our homes, offices, etc. Read on to learn more about our lead-free solder paste solutions.

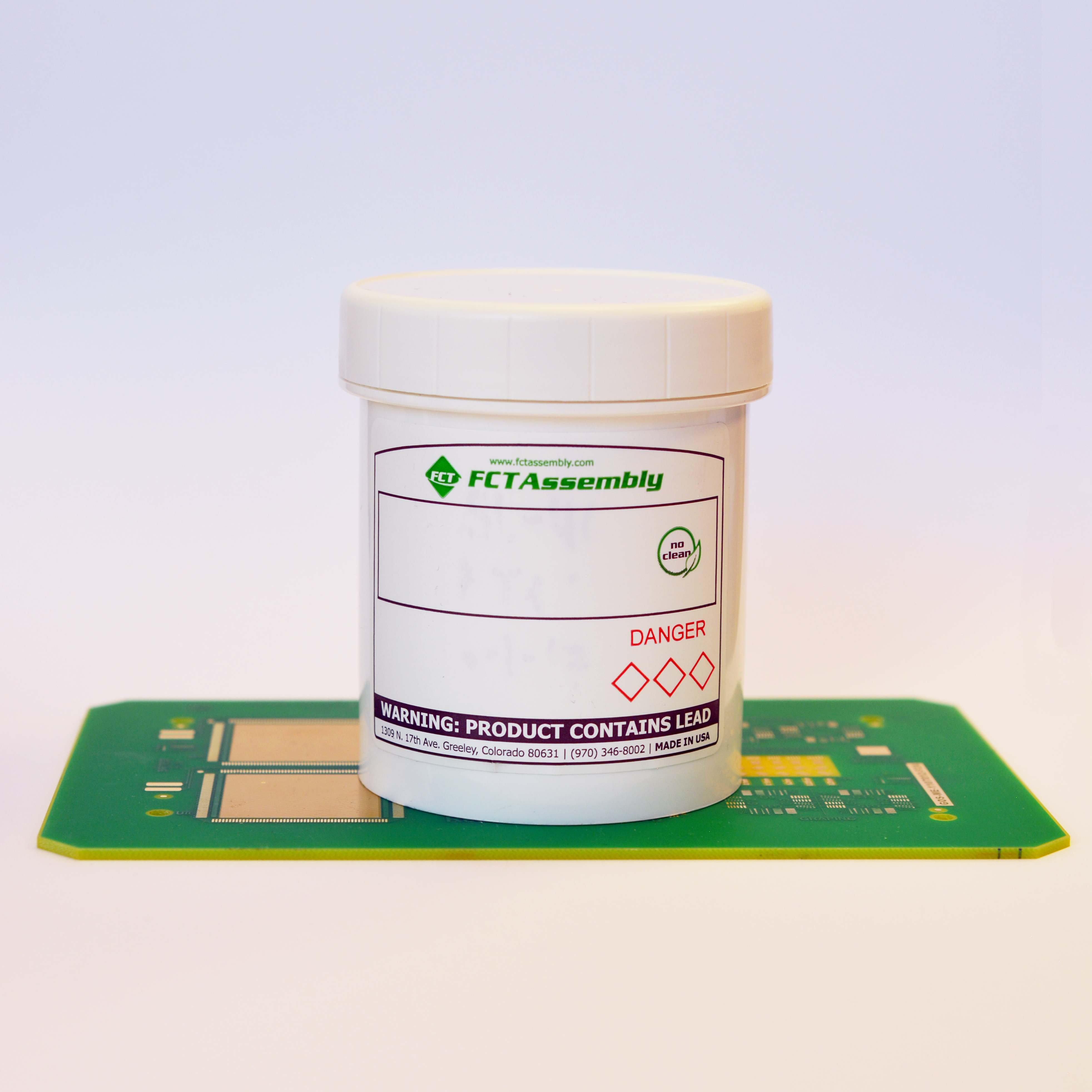

Leaded Solder Paste

Those who partake in projects that are not for public or commercial use might benefit from a leaded solder paste due to its high melting point. Less heat is required when using leaded solder paste, making it an easy solution for one-off technical projects. As hobbyists and other DIY-ers do not typically use a commercial amount of solder, but in fact, much less, the opportunity for landfill contamination is far less than otherwise. Find out if leaded solder paste is right for you.

No Clean Solder Paste

In an effort to eliminate the water wash process, many manufacturers are moving from water soluble solder pastes to no-clean solutions. Learn about our No-Clean Solder Paste to find out if it’s right for your project.

High-Reliability Solder Paste

Cost, delivery and reliability determine manufacturing yields and are key in maintaining a successful and profitable assembly process. Learn more about which solder paste solutions are optimal for a high-reliability product.

Low Temp Solder Paste

For assemblies that might not be able to handle the high temperatures used for lead-free soldering, a low temp solution might be right for you. Learn more about solder pastes that are optimal for low temperature assemblies.

Water Soluble Solder Paste

As the industry strives to move away from the water wash process, favoring no-clean solder solutions, certain applications lend themselves to the use of water soluble solder paste. Learn more to find out if water soluble solder paste is right for your project.

Still have questions?

Lead-Free Solder Paste Solutions

The AMP One solder paste combines industry low levels of voiding performance with excellent activity and decreases the potential for solder balling and graping.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

NL930PT is a zero halide, zero halogen, lead free, no clean solder paste that is pin probable. This paste delivers area ratio (AR) paste transfer efficiencies below 0.50.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

NL932HF is a zero halide, zero halogen, lead free, no clean solder paste that allows for repeatability and consistency. This paste is formulated to deliver exceptional cosmetics and was also designed to minimize graping issues in the reflow process.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

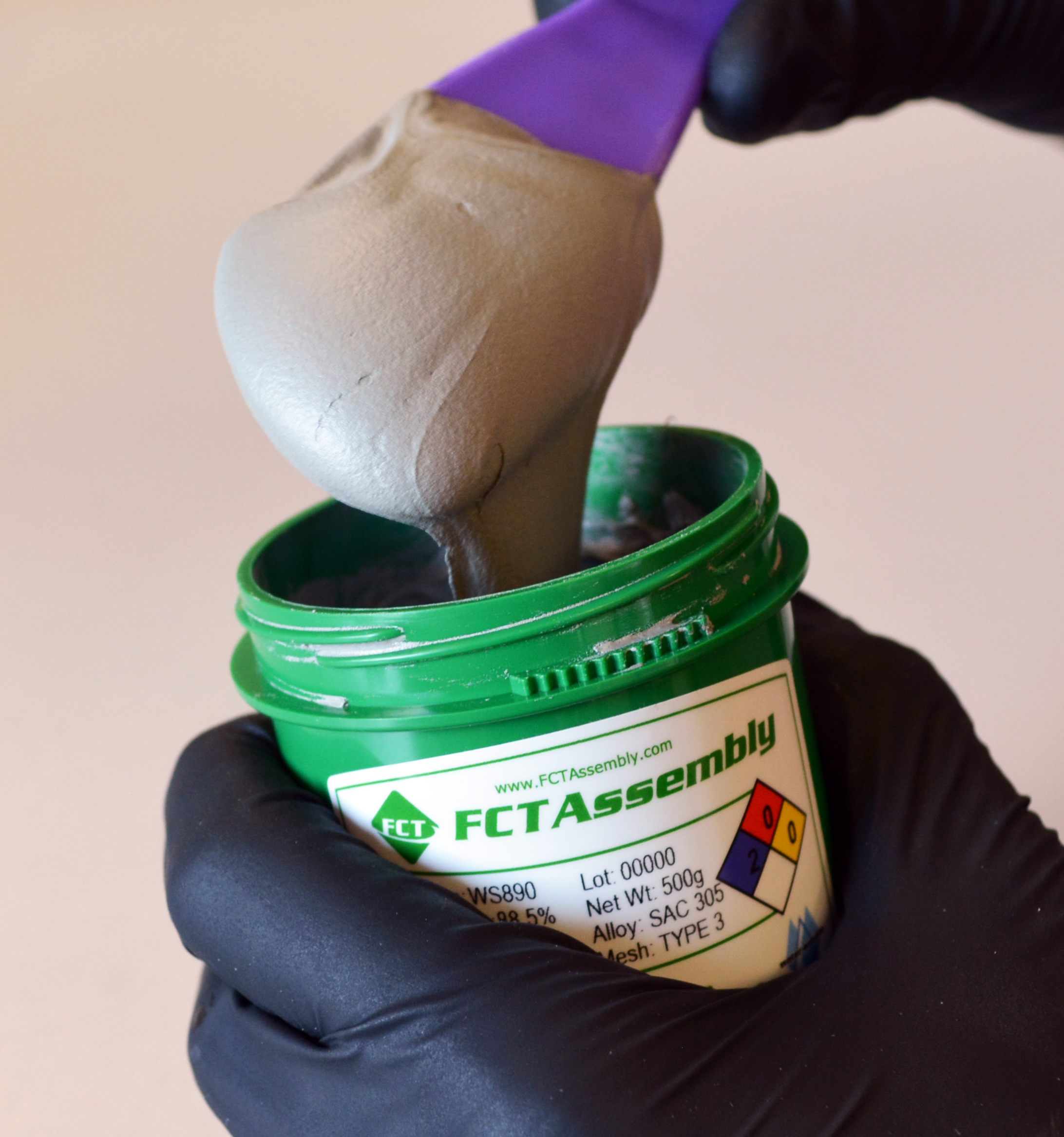

WS890 is an excellent all-around water soluble, lead-free solder paste. It has superior reflow characteristics giving excellent wetting, very low solder balling, and very low graping. WS890 has been formulated for environmental stability giving long stencil life and excellent print characteristics.

WS889 water soluble lead free solder paste is formulated to provide minimal graping and excellent wetting qualities. WS889 displays previously unseen levels of repeatability and consistency even in a wide range of temperatures (65-85 F) and relative humidity (25-65 % RH). Residues are amber in color and can be cleaned using warm water.

WS888 water soluble lead free solder paste is designed to meet the requirements for reliable solder joints in the PCB assemblies. WS888 displays previously unseen levels of repeatability and consistency even in a wide range of temperatures (65-85F) and relative humidity (25-65% RH). WS888 residues clean easily using warm water.

NC722 is a no-clean, low melting lead-free solder paste. NC722 is designed specifically for use with low melting, tin-bismuth alloys. NC722 is halide free, has excellent stencil life and is usable in a wide range of environmental conditions. NC722 flux residues are clear and pin testable. NC722 is classified ROL0.

Flux Type: No Clean

Alloys: Low melting lead free, tin bismuth alloys

Classification: ROL0

Halogen: No

Struggling to find a solution for your project?

Leaded Solder Paste Solutions

NC676

NC676 is a no clean, leaded solder paste that possesses a creamy, smooth texture. It is both halogen and halide free. This product is classified ROL0 and is a rosin-based chemistry. Residues are clear and maintain a virtually indefinite pin probability life. With its extensive tack time and long shelf life, NC676 is one of the most dependable and consistent leaded solder pastes on the market.

Attributes

- HALOGEN FREE CHEMISTRY with IPC specification of ROL0 offering a highly reliable solder joint

- Low viscosity/Low slump solder paste offering improved transfer efficiency

- Wide reflow window with good solderability on various PCB surface finishes

- Unlimited pin probability and clear post-process residues

- Cosmetically superior to most pastes offering shiny solder joints with a crystal clear, crack resistant residue

- Designed for Sn/Pb alloys and Type 3, 4, and 5 solder powders.

WS159

WS159 is a water-soluble, leaded solder paste that is classified ORH0. WS159 was formulated to meet the requirements for reliable solder joints in PCB Assemblies along with a large operating window. Thus, WS159 was designed to provide humidity tolerance and excellent wetting. WS159 remains stable in a wide range of temperatures (65-85F) and relative humidities (25-65%RH). While maintaining a stable viscosity and exceptional cosmetics, WS159 exhibits low voiding characteristics. The residue of this product is easily visible and removable with warm water.

Attributes

- Excellent print volume and repeatability with low area ratios (AR) as low as 0.50 when used with the NanoSlic stencil technology

- Environmentally stable formulation which is resistant to slump

- Wide reflow window with excellent wetting characteristics on all surface finishes

- Very stable product for a water-soluble paste that allows storage of this paste up to 6 months at room temperature and one year if refrigerated

- Compatible with either nitrogen or air reflow

- Formulated for leaded alloys and Type 3, 4, and 5 solder powders

RMA250

RMA250 is a high activity, no clean solder paste that is classified ROL1. This high activity, along with its rosin-based chemistry, allows for improved cosmetics and excellent wetting on all surface finishes. Residues left behind are clear and pin probable but can be removed using the appropriate cleaning chemistry. RMA250 has a wide reflow window with exceptional soldering activity on all surface finishes.

Attributes

- Low viscosity with low slump characteristics allow for fast printing and improved transfer efficiency

- Residues can be removed easily with the appropriate cleaning chemistry

- Wide reflow window with excellent solderability on various PCB surface finishes

- Pin probable with clear post-process residues

- Excellent cosmetics

Flux Type: No Clean

Alloys: Lead

Classification: ROL1

Halogen: Yes

Other Solder Paste Solutions

No Clean Solder Paste

No clean, lead-free solder pastes are the newest and most technologically-advanced solder pastes on the market. Due to the increased use of solder pastes with the ever-growing technology landscape, the need for a no-clean, no water solution is greater than ever. By eliminating the water washing process, fewer chemicals end up in landfills, making no clean solutions some of the most desirable in the industry.

These solutions come in several varieties with many different strengths. Some will be more beneficial for optimal printability and reflow characteristics (see NL932HF), whereas others will be best suited for in-circuit tests (NL930PT) or pin in paste applications.

The AMP One Ultra Low Voiding Solder Paste offers unmatched capability for amplifying process windows and achieving higher yields. The unique solder paste is widely utilized for its capacity to minimize voiding better than many other pastes on the market as well as it’s decreased risk of solder balling and graping.

High-Reliability Solder Paste

Technology, while powerful, is also very delicate. When electronics are designed to be utilized in extreme environments–fluctuating temperatures, humidity levels, etc.–thermal stress and thermal cycling are key. After all, each component needs to be able to withstand repeated exposure without damage or weakening. For added security in less-than-favorable environments, LF-C2 solder paste might be the right solution for your project.

Low Temperature Solder Paste

When high temperatures can cause damage to components of the assembly process, low temperature solder paste is becoming a more common solder paste solution. Low temperature solder can be used in a wide variety of ways, including solder paste, wire solder, preforms, and bar solder. The peak reflow temperature ranges from 160-170°F, approximately 80°F cooler than that of a lead-free solder assembly, ensuring that warpage and other damage is avoided.

Water Soluble Solder Paste

As the industry strives to move away from the water wash process, favoring no-clean solder solutions, certain applications lend themselves to the use of water soluble solder paste. High reliability applications typically call for water soluble solder paste, as they require removal of the flux. Given that water soluble solder flux can be easily removed with warm water, this makes it an ideal solution for projects that require an easy cleaning solution without sacrificing high reflow characteristics, excellent wetting technology and low balling and graping.

About Our Lead Free Solder Pastes

The assembly of electronics is taken to a new level of quality and precision with our diverse range of high-performance lead-free solder pastes. FCT Assembly guarantees excellence in the manufacturing of solder materials which can be used on circuit boards during the surface mount process.

Throughout our product line, we utilize common lead free alloys (SAC305, SN100C®, Sn96.5/Ag3.5) and combine them with our industry-leading flux technology.

Our R&D team is backed by over 100 years of combined experience formulating cutting-edge soldering fluxes.

The lead free era in electronics manufacturing accelerated with the advent of the EU’s RoHS (Restriction of Hazardous Substances) in 2006. This law forced electronics manufacturers to use lead free solders in their process.

SAC305 was adopted early on as the lead free alloy of choice. It has lost some popularity in wave and selective soldering applications, but remains the most popular lead free alloy for solder paste.

SN100C®: The Industry-Leading Alloy for Wave and Selective Soldering

Alternate lead free alloys like Sn96.5/Ag3.5 are used in solder paste for specific applications that are brought on by customer demand.

Leaded solder pastes differ in formulation to adhere to the variety of applications for which they are used. Some notes to keep top of mind when choosing a leaded solder paste for your project include:

- Leaded solder pastes work at lower reflow temperatures

- They use chemicals and other components that could evaporate or “burn off” in a lead-free reflow profile.

- Fluxes are usually less active than lead-free solder paste fluxes.

- Solvents and other ingredients typically have lower boiling points

Regardless of these differences in solder paste fluxes, many lead-free solder pastes out-perform their leaded counterparts while providing a more healthy and environmentally sustainable option for manufacturers.

Lead-Free is the Future.

Learn why lead-free solder paste has become the industry standard.

Due to their environmental stability, FCT Assembly lead-free solder pastes can be counted on for prolonged shelf life, stencil life, and board life. They’re known for high-quality performance during the printing process.

The stencil life is prolonged to make the most of our solder paste in an effort to minimize waste. Our adamance to formulate solder with unparalleled reflow performance is key to an optimal lifespan.

Our solder pastes are known for overall excellent performance with unbeatable wetting, balling, graping and voiding performance capacities. Several of our products are specifically formulated to minimize any additional voiding beyond the already low levels offered by our standard products.

We make solder paste fresh to order.

Our standard lead time is 3-4 working days. This ensures that you receive a product that has its entire shelf life ahead of it, ready-to-use for your next project. Nonetheless, the vast majority of our products have a shelf life of at least 9 months.

Not convinced?

Drop us a line

to learn more about our solder paste solutions.