LF-C2 High-Reliability Solder Paste

A durable solution for automotive manufacturers who need reliability in the face of extreme temperatures and high stress.

When you’re assembling electronics destined for harsh environments, thermal stress and thermal cycling are key. Every component needs to withstand repeated exposure without weakening.

Designed for these harsh environments, LF-C2 is ideal for:

Underhood ECUs | Braking electronics | Steering electronics | Exterior lighting control | High reliability in extreme environments

If you’re looking for a high-reliability alloy for under the hood, around the engine bay, and other areas with electronics, LF-C2 is an excellent choice.

The choice for when reliability matters.

Because of its creep-resistant properties, FCT Solder’s LF-C2 alloy is a common choice for underhood applications that have high operating temperatures.

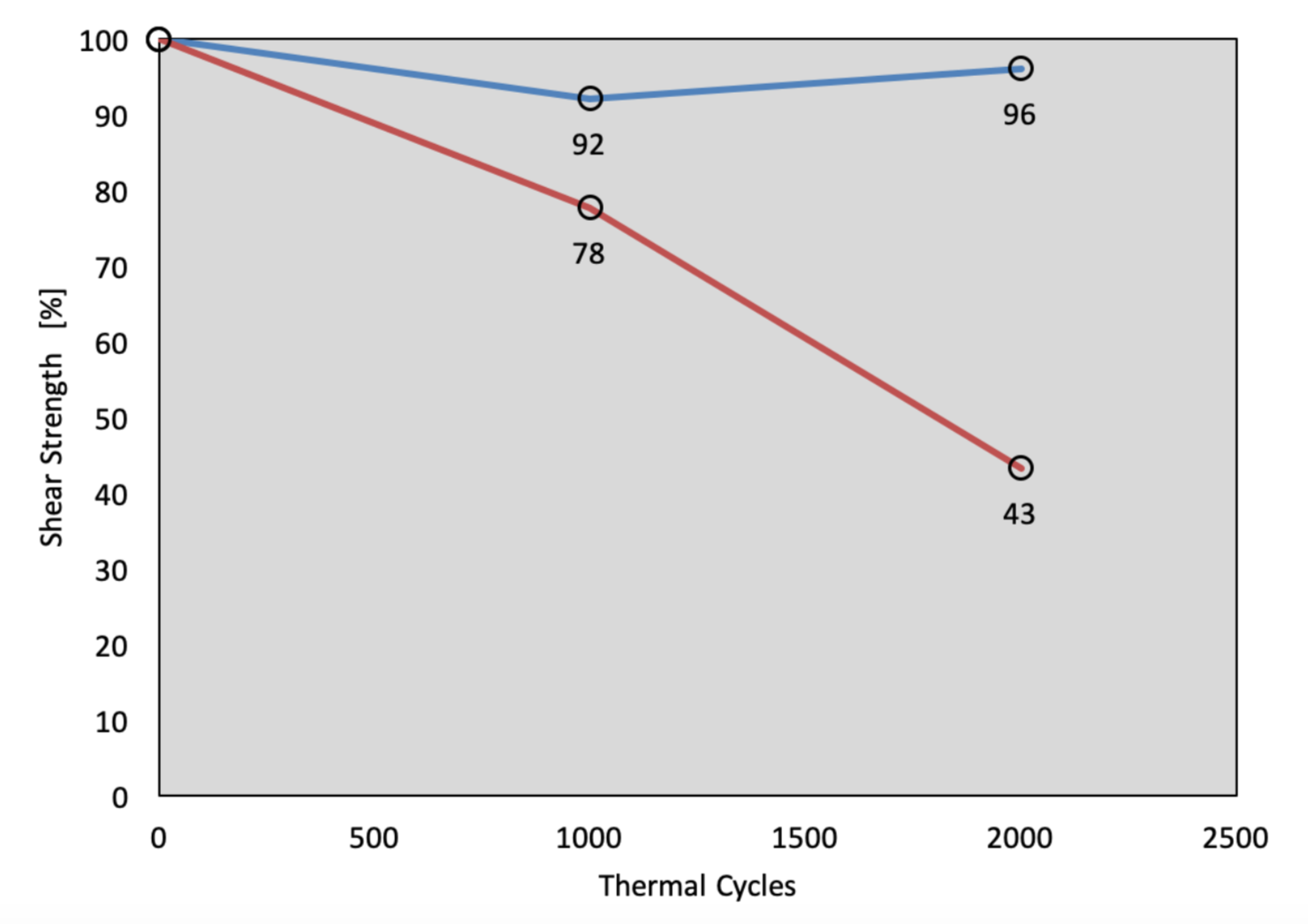

Thermal cycling weakens solder joints over a product’s life cycle. That, in turn, leads to vibration and shock issues. LF-C2 alloy’s strength creates high-integrity solder joints that hold up during harsh conditions.

How does FCT Solder’s LF-C2 alloy compare to other options?

There are some alloys, like SN100CV, that weren’t necessarily designed for harsh environments but which still hold up in certain circumstances. LF-C2, however, is made for the extremes.

When you know a component is facing extreme temperatures, vibrations, and shocks, you’ll want a choice that LF-C2 is an excellent alternative not only to traditional alloys like SAC (which don’t have the reliability needed for these high-stress applications), but also to other high-reliability alloys on the market, which are often plagued by voiding issues.

Below is a shear strength comparison between LF-C2 and SAC alloys during extended thermal cycling:

SHEAR STRENGTH COMPARISON

BLUE: LF-C2 | RED: SAC305

COMPONENT: R2125

Interested to Learn More?

Fill out the form below!

Oops! We could not locate your form.