No Clean Solder Paste

Today’s no clean lead-free solder pastes are the newest, high technology solder pastes on the market. Research and development efforts have been focused on no clean lead-free solder pastes due to the increasing use of these products. Water-soluble, lead-free solder pastes are still used, but the volume of consumption is declining.

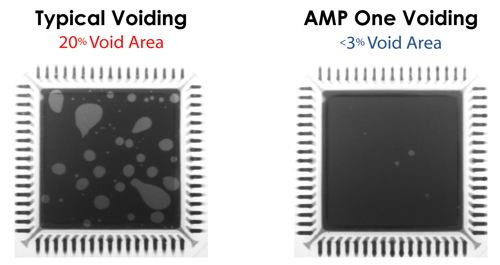

No clean solder pastes are formulated with many different strengths. Some solder pastes display excellent printability and superior reflow characteristics like our NL932HF solder paste. Certain no-clean solder pastes are geared to perform well for the in-circuit test (NL930PT) or pin in paste applications. Other solder pastes give ultra-low voiding performance like our Amp One solder paste.

No clean solder pastes generally outperform water-soluble solder pastes. No clean solder pastes tend to be less reactive and more environmentally stable than water-soluble solder pastes which result in longer stencil life, longer abandon time, and longer shelf life.

No clean solder pastes perform well in challenging environmental conditions (e.g. 90°F and 80% RH) where water soluble solder pastes quickly become unusable.

No clean solder pastes print well through challenging aperture area ratios and give optimal reflow performance.

Newer water-soluble solder pastes can perform as well as no clean solder pastes, but these newer water-soluble solder pastes are much less common.

No clean solder pastes are popular because the flux residues do not need to be washed off of the circuit board after reflow. This simplifies the surface mount assembly process and improves productivity.

The elimination of the wash process also allows for the use of components that cannot be exposed to water.

No clean fluxes are classified through the standard IPC J-STD-004B. Most use rosins (RO) as the main ingredient. It typically displays low activity (L) towards metals, and some contain halide ions (1) while others are halide free (0).

Typical classifications for no-clean solder paste fluxes are ROL1 or ROL0. Fluxes with these classifications are accepted as safe to leave on the circuit board and should not cause detrimental effects.