Solder Paste: Type 3 vs. Type 4 vs. Type 5

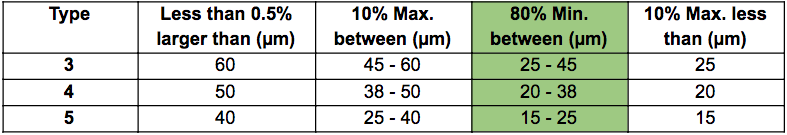

Solder paste can be made with a variety of solder powder sizes. Solder powder sizes are classified by Type in the IPC standard J-STD-005 Requirements for Soldering Pastes. Table 3-2 details the solder powder size ranges for each type, and an excerpt from the table is shown below*.

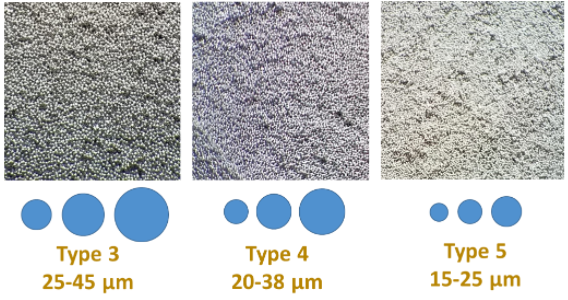

The main particle size range is normally associated with the type. For example, Type 3 solder powder mainly falls within the 25 – 45 µm size range, therefore Type 3 solder paste may be labeled as “Type 3 (25-45 µm).” Below are images of these three sizes of solder powder.

Why use Type 4 or 5 solder powder rather than Type 3?

The main reason to use Type 4 or Type 5 solder paste is to improve printability for miniature components. Type 4 and Type 5 solder pastes can be printed through smaller stencil apertures than Type 3 solder paste. Generally speaking, Type 3 solder paste can be used for components ranging in size down to the 0402 imperial package size. Most solder paste users prefer Type 4 solder paste for 0201 imperial, 01005 imperial, micro-BGAs and similar components. Type 5 solder paste is typically used for even smaller soldering applications, or when Type 4 solder paste does not print adequately.

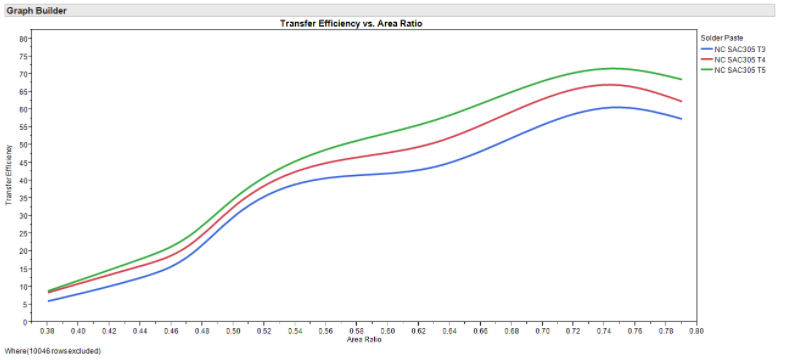

A comparison of print data for Type 3, 4, and 5 no-clean, lead-free solder pastes is shown in chart below. Transfer efficiency was measured across a variety of stencil aperture area ratios ranging from 0.38 to 0.80.

In general, Type 5 gives higher transfer efficiency than Type 4 solder paste, and Type 4 gives higher transfer efficiency than Type 3 solder paste. At smaller area ratios this difference in transfer efficiency becomes less distinct.

Type 4 or 5 solder pastes enhance printing for miniaturized components. This is especially true when these solder pastes are coupled with stencil technologies designed to enhance printing. Fine grain laser cut steel stencils along with NanoSlic Gold coating give a substantial increase in transfer efficiency as compared to standard steel stencils. The increase in transfer efficiency is dramatic when Type 4 or 5 solder pastes are used along with fine grain steel stencils coated with NanoSlic Gold. This combination allows for printing of even the finest of components.

Smaller solder powder sizes like Type 4 and Type 5 give improved printability but also can create some issues due to chemical reactions with the solder powder. The surface area of the smaller solder powder types is significantly higher than the larger solder powder types. For the same mass of solder powder, the surface area of Type 4 solder powder is roughly 20% higher than Type 3, and the surface area for Type 5 solder powder is roughly 75% higher than Type 3.

The rate of chemical reaction with the solder powder is directly proportional to the surface area of the solder powder. Therefore, smaller solder powders react more quickly than larger solder powders. This higher rate of reaction leads to potential issues when using Type 4 and 5 solder pastes.

The shelf life of Type 4 and 5 solder paste is typically shorter than Type 3 due to a higher rate of reaction between the flux and solder powder. Type 4 and 5 solder pastes can generate more random solder balling and graping than Type 3 with certain solder paste formulations. This is due to a higher potential for oxidation of Type 4 and 5 solder powders. Most solder paste manufacturers correct these issues by adjusting the formulas for Type 4 and 5 solder pastes. Newer Type 4 solder pastes typically perform equal to or better than Type 3 solder pastes.

FCT Assembly is ready to meet your needs for Type 3, 4 and 5 solder pastes. We manufacture and sell a wide variety of soldering products including wire solder, bar solder, liquid flux, gel flux, and solder pastes.