E-Z Step Stencils

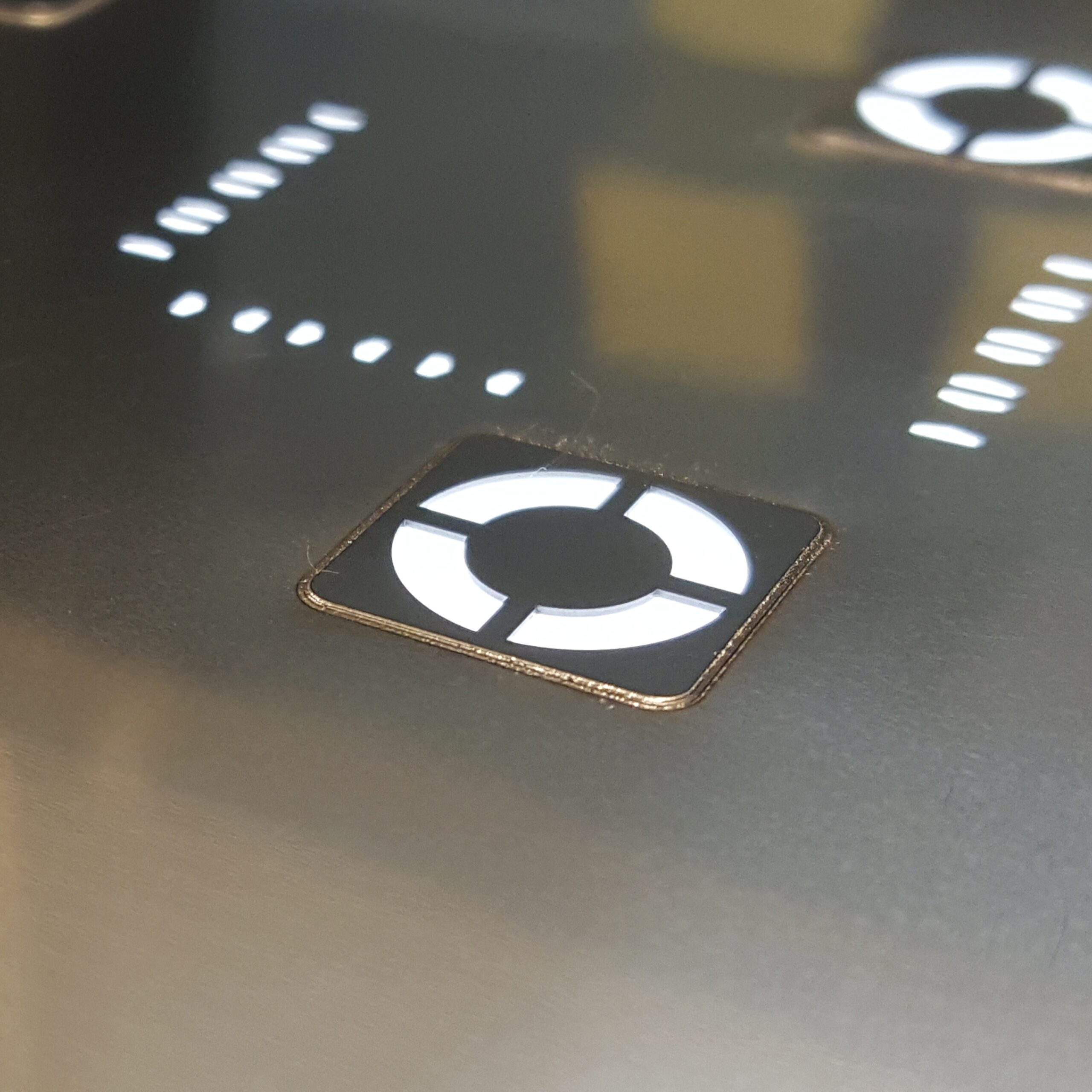

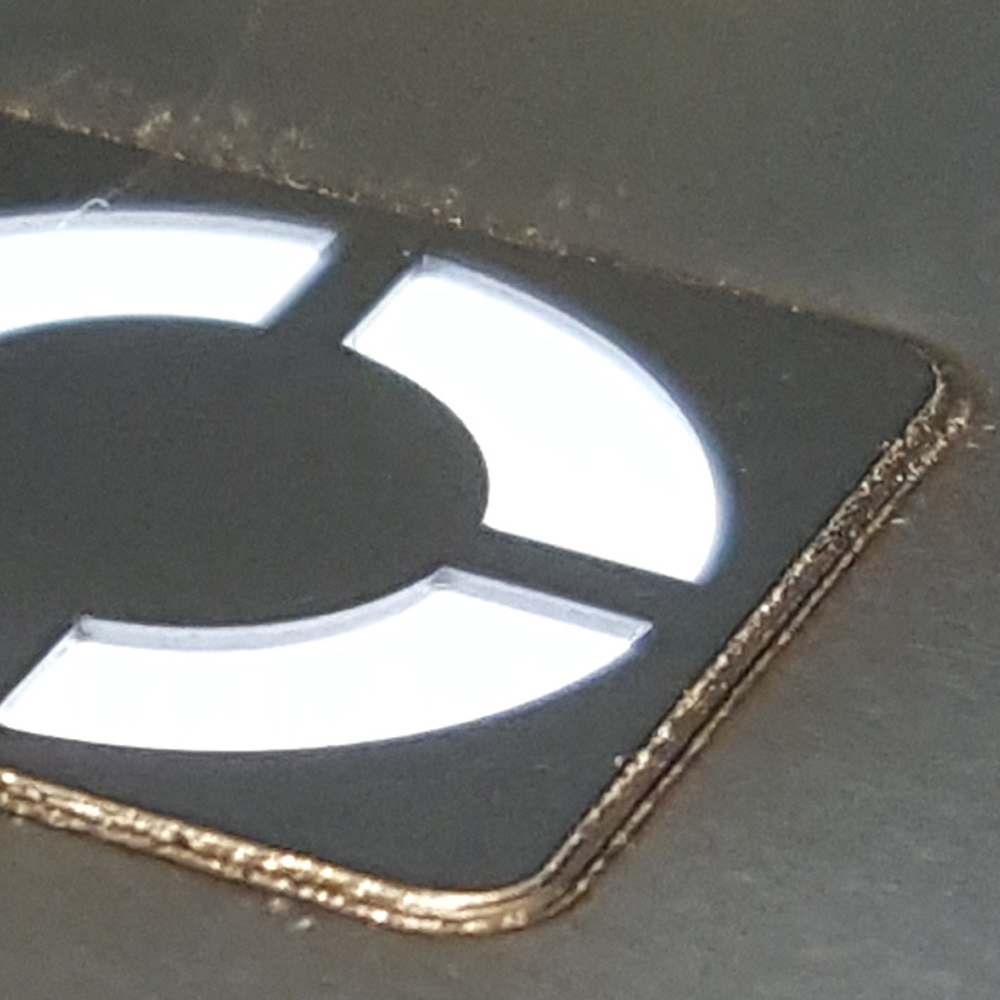

Our revolutionary laser welded E-Z Step stencils are used to facilitate an increased or decreased amount of solder paste volume and to deposit a specific brick height on selected PCB areas where you have mixed component technology, large ground pads, intrusive reflow or areas with co-planarity issues.

Advancements to Step Technology

Stronger Weld

Greater Range in Steps

Flatter Weld

SPECIFICATIONS

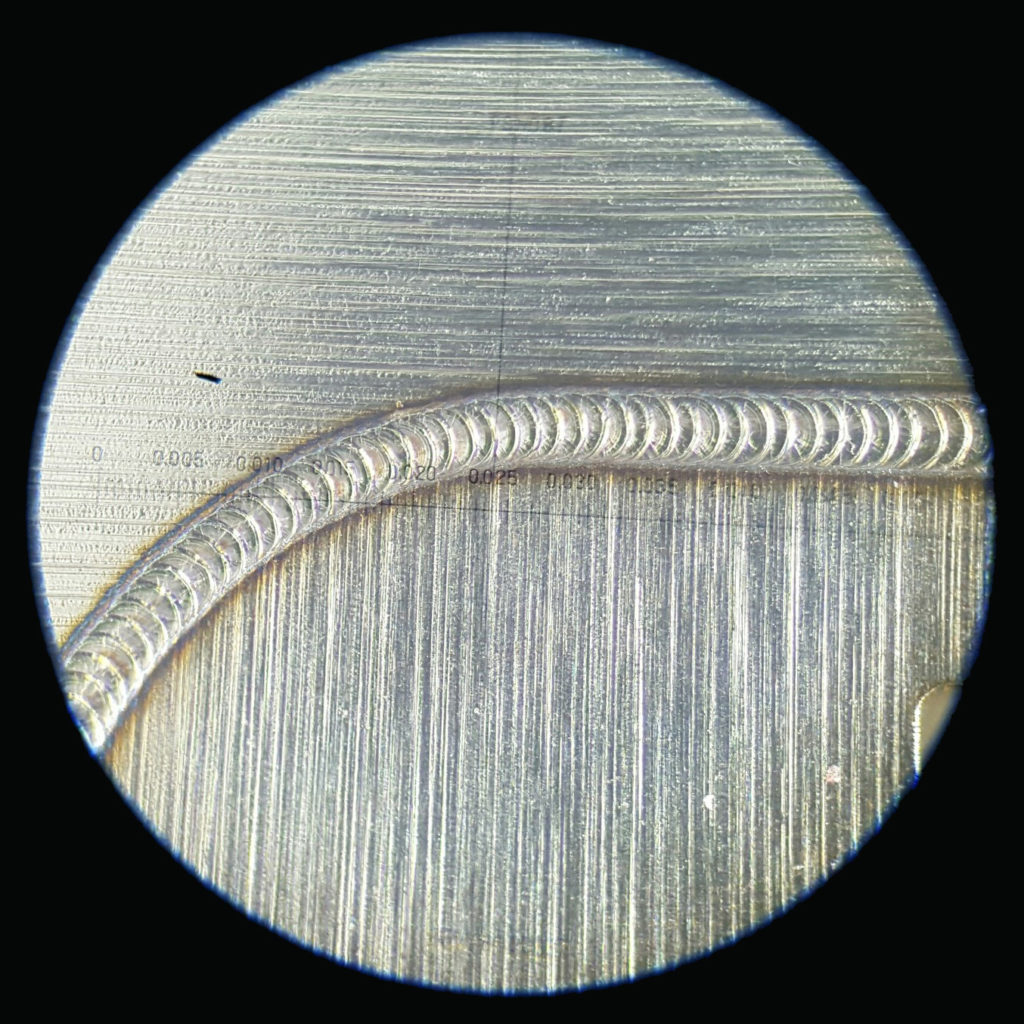

Step areas

Step ramp

Positional accuracy

Material thickness

Board side distortion

Environmentally friendly

Process

Thickness

Lead-time

20 – 150 microns with support for complex shapes

Controlled step ramp in 50 micron increments

< 10 microns on the step areas

+/- 2% (primary steel and step steel)

Flat with no impact

No hazardous chemicals or pollutants used in process

Provides increased control over your print process

Vary to generate exact paste volume & height for every component

Same day quick turn service available