Lead Free Solder Paste

The AMP One solder paste combines industry low levels of voiding performance with excellent activity and decreases the potential for solder balling and graping.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

NL930PT is a zero halide, zero halogen, lead free, no clean solder paste that is pin probable. This paste delivers area ratio (AR) paste transfer efficiencies below 0.50.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

NL932HF is a zero halide, zero halogen, lead free, no clean solder paste that allows for repeatability and consistency. This paste is formulated to deliver exceptional cosmetics and was also designed to minimize graping issues in the reflow process.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

WS890 is an excellent all-around water soluble, lead-free solder paste. It has superior reflow characteristics giving excellent wetting, very low solder balling, and very low graping. WS890 has been formulated for environmental stability giving long stencil life and excellent print characteristics.

WS889 water soluble lead free solder paste is formulated to provide minimal graping and excellent wetting qualities. WS889 displays previously unseen levels of repeatability and consistency even in a wide range of temperatures (65-85 F) and relative humidity (25-65 % RH). Residues are amber in color and can be cleaned using warm water.

WS888 water soluble lead free solder paste is designed to meet the requirements for reliable solder joints in the PCB assemblies. WS888 displays previously unseen levels of repeatability and consistency even in a wide range of temperatures (65-85F) and relative humidity (25-65% RH). WS888 residues clean easily using warm water.

NC722 is a no-clean, low melting lead-free solder paste. NC722 is designed specifically for use with low melting, tin-bismuth alloys. NC722 is halide free, has excellent stencil life and is usable in a wide range of environmental conditions. NC722 flux residues are clear and pin testable. NC722 is classified ROL0.

Flux Type: No Clean

Alloys: Low melting lead free, tin bismuth alloys

Classification: ROL0

Halogen: No

Want to learn more?

About Our Lead Free Solder Pastes

FCT Assembly manufactures and sells high performance lead free solder pastes for electronics assembly. Our products are intended for use soldering components onto circuit boards in the surface mount process.

We utilize common lead free alloys (SAC305, SN100C®, Sn96.5/Ag3.5) and combine them with our industry leading flux technology.

Our research and development chemists have over 100 years of combined experience formulating soldering fluxes.

The lead free era in electronics manufacturing accelerated with the advent of the EU’s RoHS (Restriction of Hazardous Substances) in 2006. This law forced electronics manufacturers to use lead free solders in their process.

SAC305 was adopted early on as the lead free alloy of choice. It has lost some popularity in wave and selective soldering applications, but remains the most popular lead free alloy for solder paste.

SN100C® is now the industry-leading alloy for wave and selective soldering, and has some market share in solder paste applications.

Alternate lead free alloys like Sn96.5/Ag3.5 are used in solder paste for specific applications which are driven by customer needs.

Leaded solder pastes differ in formulation because they:

- Work at lower reflow temperatures

- Use ingredients that could evaporate or “burn off” in a lead free reflow profile.

- Fluxes are usually less active than lead free solder paste fluxes.

- Solvents and other ingredients typically have lower boiling points

Regardless of these differences in solder paste fluxes, many lead free solder paste out-perform their leaded counter parts.

Leaded solder paste technology has fallen behind the newer, more advanced lead free solder pastes.

FCT Assembly lead free solder pastes are environmentally stable which prolongs shelf life, stencil life, and board life. Our solder pastes perform exceptionally well in the print process.

Stencil life is optimized to allow for the complete use of our solder paste in order to minimize waste. We formulate solder paste with exceptional reflow performance.

Wetting, solder balling, graping, and voiding performance are all optimized. We offer solder pastes that are specially formulated to minimize voiding beyond the already low levels offered by our standard products.

We make solder paste fresh to order.

Our standard lead time is 3-4 working days. This ensures that your solder paste has its full shelf life, which is 9 months for most of our products.

Not convinced?

We’re happy to provide samples of our solder pastes for testing.

Restriction of Hazardous Substances (RoHS)

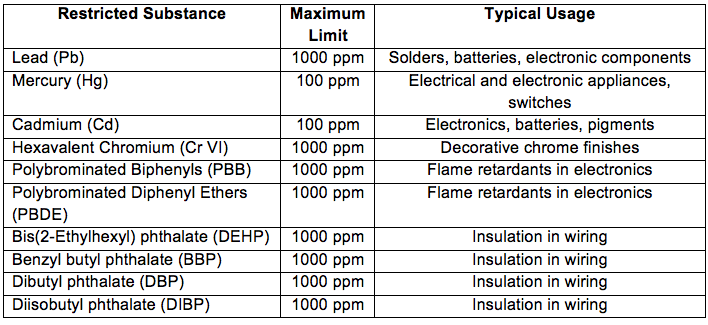

The usage of lead free solder in electronics accelerated with the implementation of the European Union’s Directive 2002/95/EC on the Restriction of Hazardous Substances (RoHS). These laws took effect on July 1, 2006. The restricted substances included in RoHS are shown below:

The intention of RoHS is to reduce the amount of these substances introduced to the environment.

This forced many electronics manufacturers to use solders that are free of lead, mercury, and cadmium.

Most lead free solders are based on tin (Sn) and contain a trace amount of lead (Pb) that is below the RoHS limit (1000 ppm = 0.1 % wt).

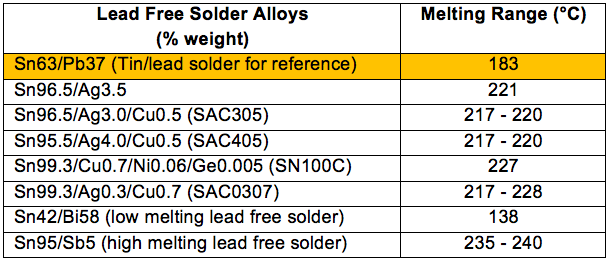

The process of using lead free solders requires higher temperatures than lead bearing solders.

This is due to the higher melting points of most tin based lead free solders, which are shown below:

In most cases the melting point of lead free solders is 35 to 40 °C higher than Sn63/Pb37 solder.

Lead free solders require higher temperatures in wave, selective, hand, and reflow soldering. The fluxes, circuit boards, and components used must be able to handle this additional heat.

Since the implementation of RoHS, soldering fluxes have been developed to give excellent performance with lead free solders. FCT Assembly manufactures and sells a wide variety of lead free soldering products. These include wire solder, bar solder, liquid flux, gel flux, and solder pastes.