FCT Assembly has partnered with Nihon Superior to be able to offer their patented lead-free nickel stabilized tin/copper wave solder alloy – SN100C worldwide. SN100C was developed to offer a technically superior and more economical option to the tin-silver-copper alloys also being considered. SN100C is also significantly less costly than other tin alloys including SAC305.

Suitable for Micro-Soldering

The finely dispersed microstructure of SN100C makes it possible to roll very thin foil without defects.

The melting behavior of SN100C (Sn-0.7Cu-0.05Ni+Ge) provides excellent characteristics during reflow. Low intermetallic growth provides high reliability and flexibility.

Trusted Worldwide

SN100C is being used in thousands of wave soldering machines around the world and has proved its reliability in products exposed to the most severe service environments.

The product has been patented in 23 countries and regions including the United States and Japan. Manufacturers trust SN100C to deliver high quality consistently.

Superior Reflow Characteristics

SN100C Solder Paste along with a linear profile enables reflow with temperatures similar to SAC305 with a 245 °C peak temperature.

SN100C features a reduction of hot slump, fast melting speed, excellent wetting force, and reduction in reflow time by about 10%.

SN100C Properties

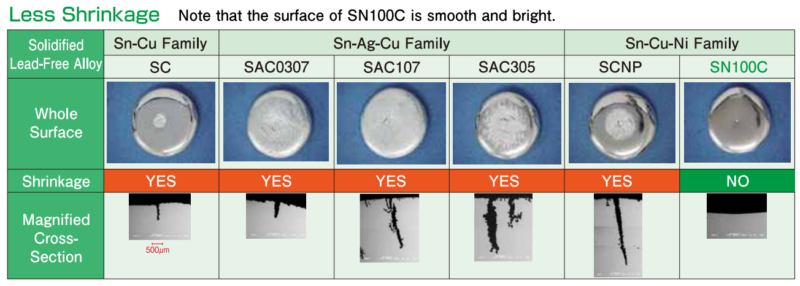

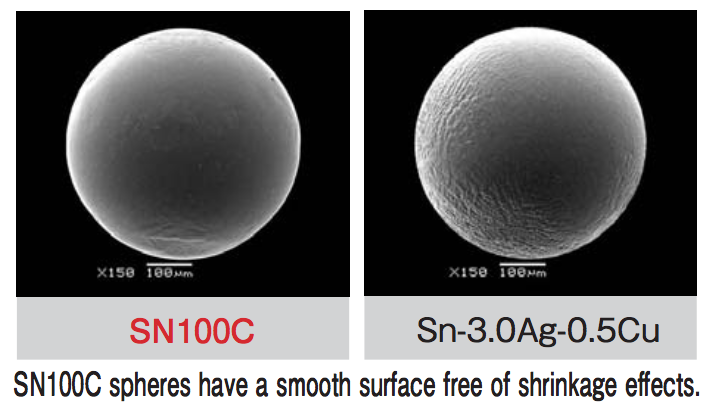

SN100C freezes with a smooth surface giving it a shiny appearance like Sn63/Pb37. SN100C and Sn63/Pb37 are eutectic solders, which means that these solder alloys melt and freeze at a single temperature.

SN100C melts and freezes at 227 °C.

Sn63/Pb37 melts and freezes at 183 °C.

Solders which melt and freeze over a temperature range like SAC305 (217 – 220 °C) tend to have a dull, grainy, and cracked surface. SAC305 alloy can corrode the steel used in older solder machines. Corrosion typically starts at the hot spots near heaters and at weld joints. Once corrosion begins then it will slowly continue until there is a penetration resulting in a leak. SN100C is compatible with and non-corrosive towards the steel alloys commonly used in wave and selective soldering machines.

Eutectic solders like SN100C melt and freeze at a single temperature rather than over a temperature range. Eutectic solders typically have a uniform grain structure which results in a bright and shiny appearance.

SN100C solder composition tends to change over time and as the elemental composition moves away from nominal, performance tends to degrade. Periodic analysis of the solder composition followed by recommended adjustments is an easy way to maintain optimal performance. The key elements in SN100C solder are copper, nickel and germanium. Copper and nickel concentrations are typically stable and do not usually require adjustment. Germanium tends to decrease over time and is maintained through additions of AO1000 anti-oxidant.

SN100C typically costs about 30% less than SAC305 solder alloy. This is due to the high cost of silver which makes up 3% of the weight of SAC305 solder. SN100C does not contain silver which reduces the cost significantly.

SN100C solder creates less dross than SAC305 alloy. This is due to germanium which is the primary anti-oxidant in SN100C alloy. Germanium reduces the drossing rate of SN100C which results in a lower operating cost than SAC305 alloy.

About Bar Solder

Solder can be made into many different physical forms including wire, bar, and powder. Solder bar is simply solder in bar form. This form of solder is typically used in wave solder and selective soldering machines.

FCT Assembly manufactures bar solder in many shapes including triangular and feeder bar. FCT Assembly uses a casting process in a nitrogen atmosphere to produce bar solder with a very low oxide content.

FCT Assembly specializes in manufacturing and sales of SN100C® bar solder. SN100C is a silver-free, lead-free alloy with the following elemental composition: Sn / Cu 0.70% / Ni 0.06% / Ge 0.005%. SN100C solder is the world leading alloy for wave and selective soldering applications. SN100C alloy also performs very well in solder paste and wire solder forms.

FCT Assembly manufactures and sells a wide variety of soldering products. These include wire solder, bar solder, liquid flux, gel flux, and solder pastes. Please contact us for more details.