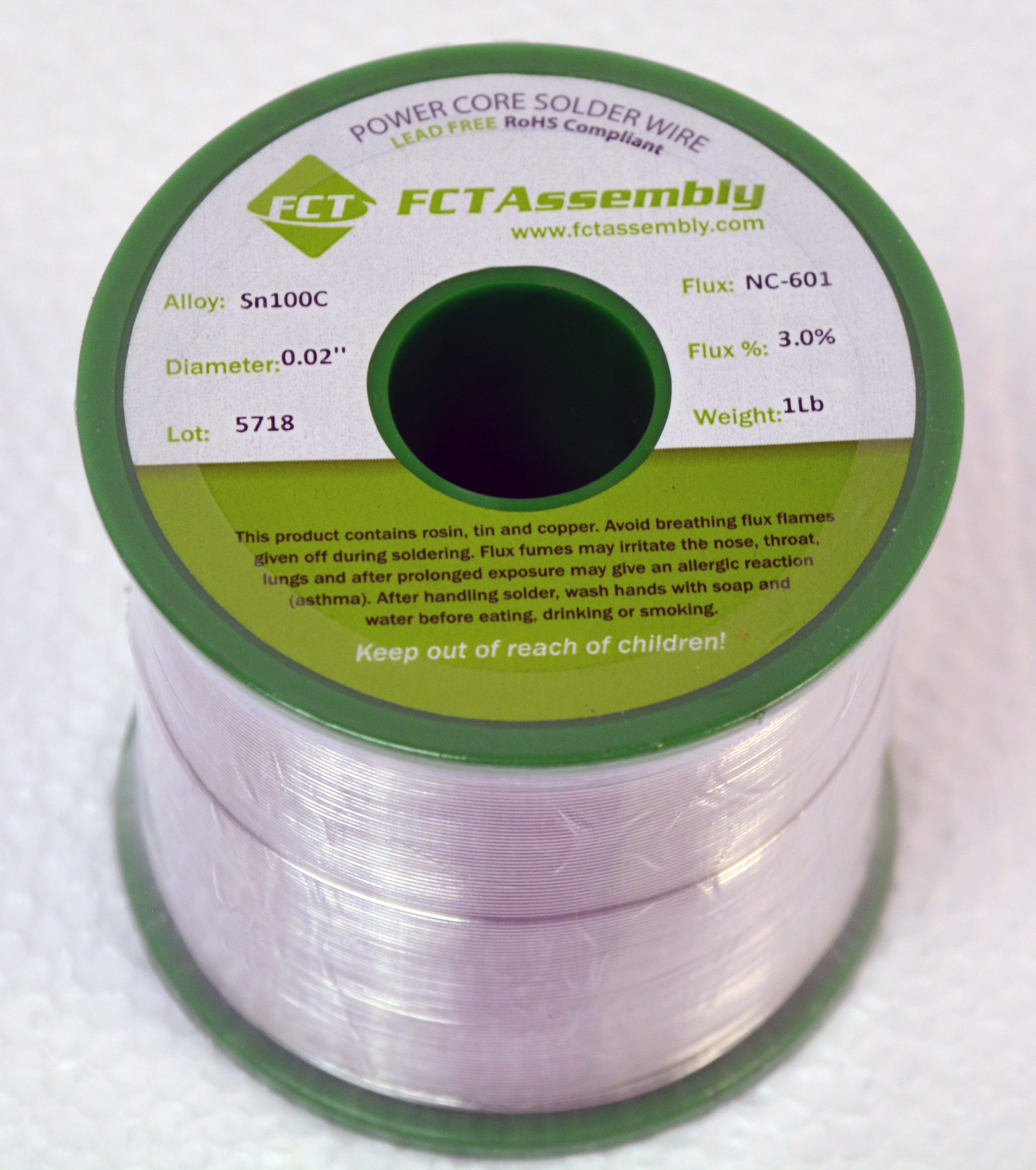

FLUX CORE & WIRE SOLDER

NC601

NC601 Power Core Wire Solder is a Rosin Activated (RA) activated no clean for repairing through-hole, mixed, and surface mount assemblies. The flux core provides faster melting and higher activity than typical RA flux cores. Its flux is formulated to provide clear, colorless residues. It also allows for maximum activity and high reliability without cleaning, in most situations.

Flux Type: No Clean

Flux Percentage: 3%

Alloys: SN100C, SAC305

Classification: ROL0

Available Diameters: 0.015, 0.020, 0.032, 0.048, 0.062, 0.098, 0.125

WS101

WS101 Power Core Wire Solder is a high activity water washable solder for repairing through-hole, mixed, and surface mount assemblies. The flux core provides faster and better flux activity than RA flux cores. WS101 flux is formulated to provide high activity soldering, leaving an easily washable residue without the need for cleaning additives.

Flux Type: Water Soluble

Flux Percentage: 2%

Alloys: SN100C, SAC305

Classification: ORH1

Available Diameters: 0.015, 0.020, 0.032, 0.048, 0.062, 0.098, 0.125

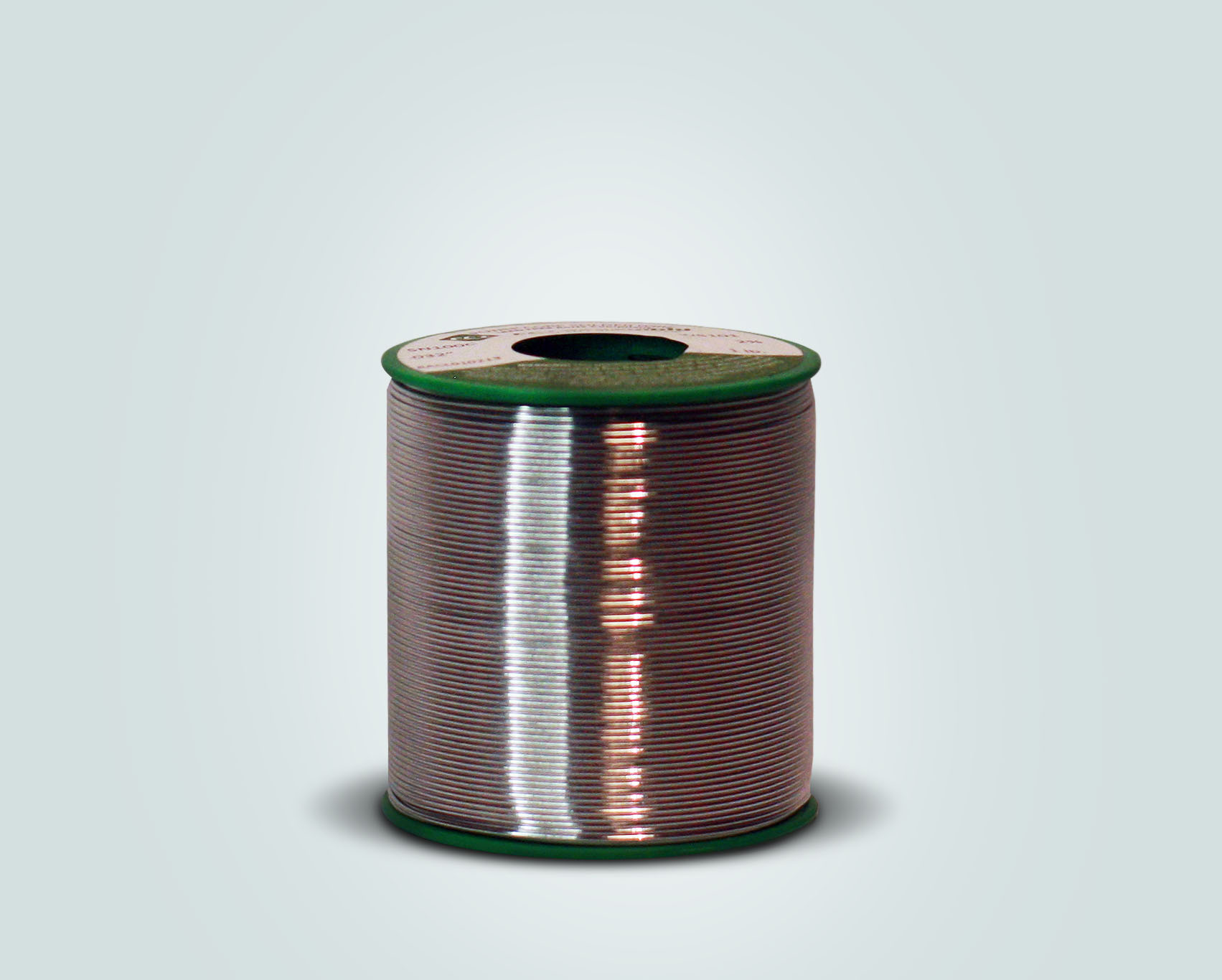

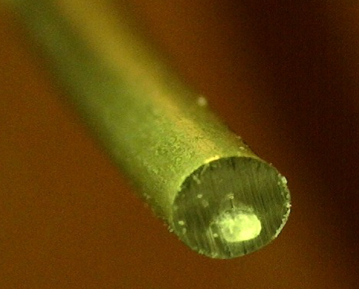

About Flux Core Solder

Flux core solder commonly refers to wire solder that has flux in the center of the wire. The concentration of flux inside of wire solder is typically 2% to 3% by weight. Without flux, wire solder would be difficult to use. The metal surfaces being soldered have an oxide layer and heating these surfaces during soldering increases the oxide thickness.

Flux is required to penetrate the oxides and clean the metal surfaces so the solder can bond properly. The flux melts first, cleaning the metal surfaces for a better joint. In many cases, flux cored wire solder is used along with a liquid or gel flux. This additional flux further improves soldering, especially with difficult to solder surfaces.

What is flux core solder used for?

Flux core solder is used for a wide range of electrical applications, including the repair of through-hole, mixed, and surface mount assemblies. It’s ideal for commercial hand soldering applications.

Benefits of using flux core solder

Flux core solder makes wire soldering much easier by cleaning metal surfaces as it melts, yielding a better joint. Flux makes solder joints stronger by cutting down on voids. It also helps bonding to improve contact. Some types of flux core solder, such as those sold by FCT Assembly, can be used with metals that have traditionally been difficult to solder, including brass, nickel, and oxidized copper.

Types of flux core solder

Flux cored wire solder is available with no clean and water-soluble fluxes, and is made from common solder alloys.

No clean flux core solder generally does not require any residue be removed after soldering. Water-soluble fluxes usually only need to be washed with water, rather than cleaning additives.

Traditionally, flux core solder has been made with high-lead (Pb) alloys. However, the industry is moving away from the use of lead because of the associated health risks and regulations. The flux core wire solder sold by FCT Assembly is lead-free.