Liquid Solder Flux

WIL-1

FCTA WIL-1 is a VOC FREE low activity & solids, no-clean, wave soldering flux. It is designed to make the transition from tin-lead to lead-free wave soldering as efficient and profitable as possible. WIL-1 provides best in class productivity combining extremely high electrical reliability with excellent solderability, ultra-low residue and no white residues.

Attributes

- NC VOC Free wave Flux PB-Free & Tin-lead

- Pin testable

- Residues free post-process

- Wide Process Window

- Halogen Free

- For Selective & Wave solder Process

- Excellent Micro-Solderball Resistance

- Flux Type: No Clean

- Base: Water

- Alloys: Lead & Lead Free

- Halogen: Yes

- Classification: ORL0

- Shelf Life: 3 years

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair Pen

NC165

NC165 flux is no clean activated material for wave soldering through-hole, mixed, and surface mount assemblies. NC165 is completely halide free, meaning it possesses no hidden halide. This product is great to use when less flux residue is desired as it has a lower solids content. NC165 is formulated to work with FCT Assembly’s SN100C Bar Solder and standard Sn/Pb alloys. This product is classified ROL0 and eliminates solder balls while providing excellent solderability. NC165 is completely halide and halogen free. It is suitable for wave and selective soldering.

Attributes

- Halide free

- Very little residue

- Eliminates solder balling

- Low rosin content

- High activity level

- Shiny cosmetics

- Flux Type: No Clean

- Base: Solvent

- Alloys: Lead & Lead Free

- Halogen: No

- Classification: ROL0

- Shelf Life: 3 years

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair Pen

NC160

NC160 no clean flux is a highly activated material that works well for wave soldering through-hole, mixed, and surface mount assemblies. This product was formulated for FCT Assembly’s SN100C Bar Solder. NC160 is halide free and rosin based. It allows for the elimination of solder balls while providing excellent solderability with minimal flux residue so that cleaning is not necessary. This product is classified ROL1. Usable for wave and selective soldering.

Attributes

- Halide free

- Eliminates solder balls

- Minimal flux residue to eliminate cleaning

- High activity level

- Flux Type: No Clean

- Base: Solvent

- Alloys: Lead & Lead Free

- Halogen: Yes

- Classification: ROL0

- Shelf Life: 3 years

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair Pen

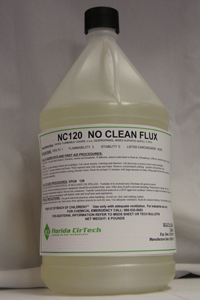

NC120

NC120 no clean flux was formulated for wave soldering through-hole, mixed, and surface mount assemblies. As a result of it’s halide free, low residue, non-rosin properties, NC120 helps to eliminate bridges or icicles along with providing excellent solderability with minimal flux residue. This product has 2% organic solid content and is classified ORL0. Usable for wave and selective soldering.

Attributes

- Low residue flux to help eliminate cleaning

- Halide free

- Non- Rosin

- Eliminates bridges and icicles

- Good wetting

- Flux Type: No Clean

- Base: Solvent

- Alloys: Lead & Lead Free

- Halogen: Yes

- Classification: ORL0

- Shelf Life: 3 years

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair pen

159HF

159HF is a halide and halogen free, neutral pH, water soluble liquid flux. 159HF is formulated to provide excellent wetting and high temperature tolerance. It provides excellent ionic cleanliness after water cleaning and has been formulated to minimize foaming in the wash process. 159HF is excellent for both wave and selective soldering applications. 159HF is also suitable for surface mount rework / touch-up soldering operations.

Attributes

- Halide and halogen free

- Water soluble

- Reduced foaming in the wash process

- Superior activity offering good solderability on all surface finishes

- Good topside wetting

- Flux Type: Water Soluble

- Base: Solvent

- Alloys: Lead & Lead Free

- Halogen: No

- Classification: ORH0

- Shelf Life: 3 years

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair pen

VOC503

VOC503 VOC Free Flux is a halide free product that eliminates solder balls while providing excellent solderability. It is no clean activated which allows the product to work well for wave soldering through-hole, mixed, and surface mount assemblies. VOC503 was formulated for Organic Surface Preservative (OSP) coated PC Boards which are difficult to solder after multiple passes through reflow. This product is classified ORH0. VOC503 is a water based product which reduces VOC content dramatically.

Attributes

- Halide free

- Water based for low VOCs

- Minimal flux residue

- Eliminates solder balling

- Allows for soldering after multiple passes through reflow process

- Flux Type: No Clean

- Base: Water

- Alloys: Lead & Lead Free

- Halogen: Yes

- Classification: ORH0

- Shelf Life: 3 years

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair pen

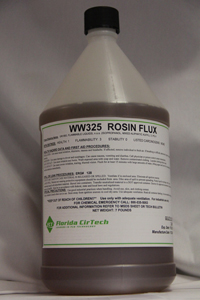

WW525

WW525 Rosin Flux is an activated, non-corrosive, type RA rosin flux that displays excellent activity and superior mobility for wave soldering through-hole, mixed and surface mount assemblies. Use of WW525 will result in faster throughput, reduced solder build-up, fewer defects, and less residue than conventional high solids type RA fluxes. WW525 is formulated to work with FCT Assembly’s SN100C Bar Solder and standard Sn/Pb Alloys. WW525 eliminates solder balls while providing excellent solderability.

Attributes

- Highly reliable

- Lower residue than conventional high solid flux

- Non-corrosive, hard, protective residue

- Flux Type: No Clean

- Base: Solvent

- Alloys: Lead & Lead Free

- Halogen: Yes

- Classification: ROL1

- Shelf Life: 1 year

Available Containers

- 1 gallon jug

- 5 gallon pail

- 55 gallon drum

- Repair pen

About Liquid Solder Flux

Liquid soldering flux is used in wave, selective and hand soldering processes. Liquid soldering flux is applied to the circuit board assembly to help the molten solder to flow and form a high-quality solder joint.

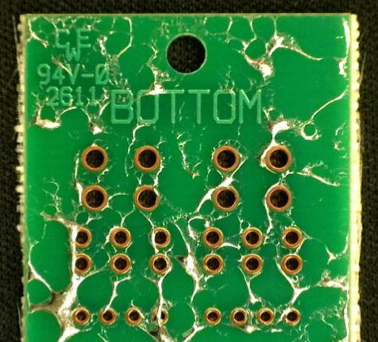

The liquid flux removes oxides from the metal surfaces and enables them to be joined together by solder. Without flux, molten solder will not bond properly to the circuit board assembly. Solder will also stick to the solder mask when flux is not used (Figure 1) because liquid flux provides some protection for the solder mask.

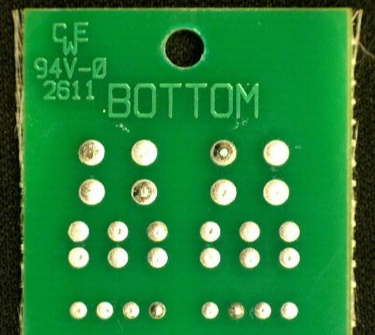

When used as recommended, liquid flux dramatically improves soldering performance (Figure 2).

Liquid flux is made up primarily of solvents and contains activators, rosins, surfactants, and other additives to enhance performance. Liquid fluxes are available in no clean and water-soluble formulations. No clean liquid fluxes are classified as safe to leave on the circuit board assembly.

Water soluble liquid flux residues must be washed off because they are corrosive to the metals on the circuit board assembly. No clean fluxes typically have much lower activity than water-soluble liquid fluxes. Water soluble fluxes are much more aggressive and are recommended for assemblies which are difficult to solder.

Liquid fluxes are available in many varieties including low solids, VOC free, halide, and halogen-free, and are formulated to be applied by spray, foam and direct application. Please fill out the form below for your liquid flux needs.