NanoSlic® Endurance

The NanoSlic chemistry was not bought, it was built from the surface up. We worked closely with industry partners to develop a top-of-the-line stencil coating. Through the use of our SMT testing lab, we were able to simulate a high production assembly environment to push the limits of NanoSlic Endurance. Our lab allows us to continue research and development of new coating technologies that adapt to our customers’ rapidly evolving processes.

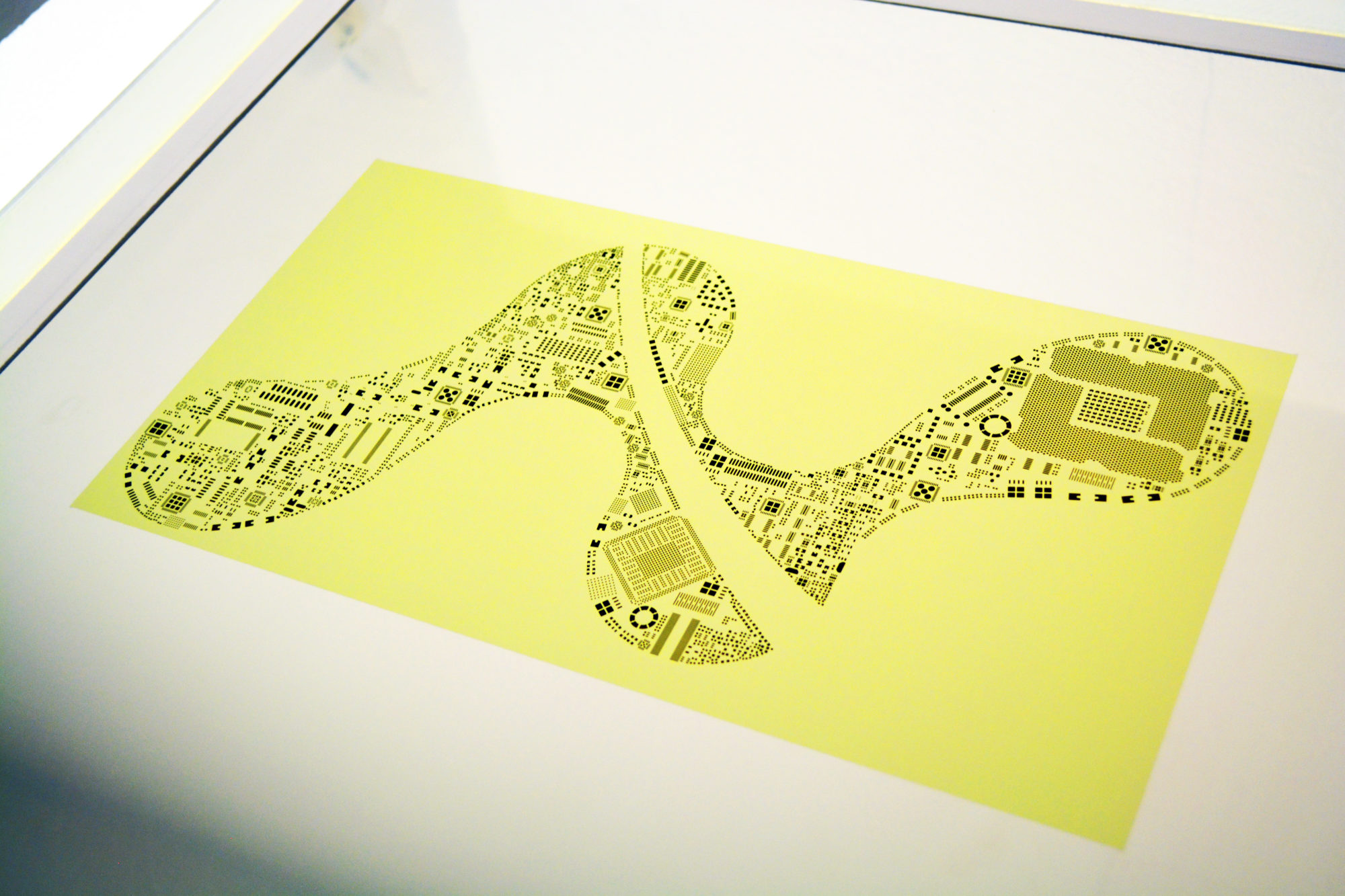

The NanoSlic® Endurance stencil is the most advanced solder paste stencil available today. The coating was developed by Florida CirTech chemists to achieve a durable, paste repelling coating that improves stencil printing significantly. Building on the proven benefits of the Slic™ stencil, advanced chemistry is used to impart a highly Hydrophobic & Oleophobic surface to the apertures and underside of the stencil. This non-stick surface resists solder paste build-up, significantly reducing the need for cleaning cycles. The Nano coating is bonded to and conforms to aperture walls regardless of size or geometry. The NanoSlic® Endurance stencil improves paste release, enabling high yield printing at low SARs (surface area ratios). NanoSlic® Endurance has a robust surface that stands up to repeated cleaning.

Now with Improved Surface Modification Process!

Our continued research and development of NanoSlic Endurance led to a breakthrough in durability and longevity characteristics. NanoSlic Endurance Stencils will now be manufactured using a New Patent Pending Surface Modification Process which offers our industry-leading surface and aperture functions with extended coating durability.

Surface Functions

Reduced underside cleaning

Improved solder brick profiles

Reduced bridging

Aperture Functions

Improved paste release

Transfer efficiency increase