How Does Printed Solder Paste Volume Affect Solder Joint Reliability

Stencil design files are typically created along with the circuit board designs. The stencil aperture sizes are often the same size as the copper pads (1:1). If solder paste was printed using these aperture sizes, then issues could occur such as solder balling or bridging. It is common practice to reduce the stencil aperture size by 10% to 50% in order to prevent such defects. This significantly reduces the volume of printed solder paste.

When fine pitch micro ball grid array (µBGA) or 0201 Imperial (0603 metric) and smaller passive components are used then the stencil thickness may be reduced in addition to reducing the aperture size. This is done to maintain the aperture area ratio above the industry standard minimum value of 0.66.

Reducing stencil thickness also reduces the volume of the printed solder paste. The solder joints created from the reduced solder paste volume must meet IPC-A-610 and J-STD-001 criteria, but are the solder joints reliable? What is the lower limit of solder paste volume required to produce a reliable solder joint? Will the solder joints survive for the lifetime of the assembly?

In order to help answer these questions, reliability testing must be performed with a range of solder volumes to determine the lower limit of the printed solder paste volume which can be used.

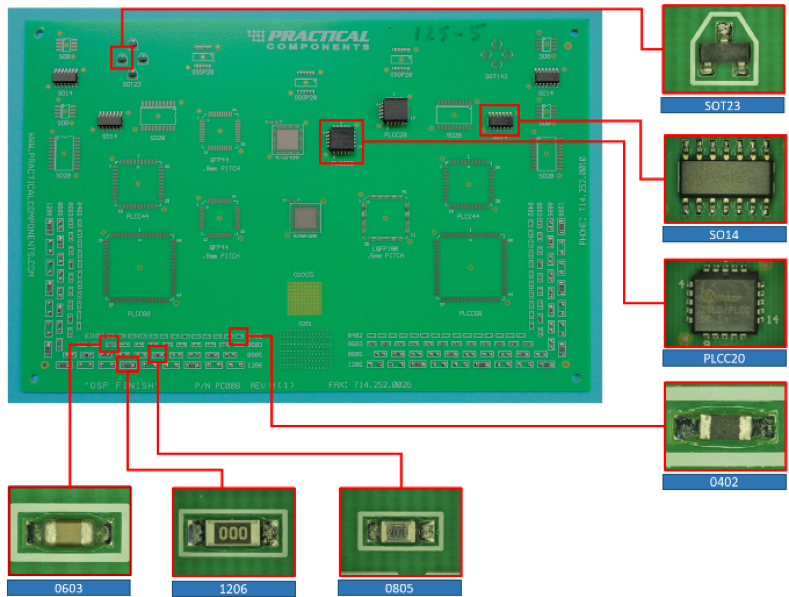

A study was conducted to answer the question of how printed solder paste volume affects solder joint reliability. The circuit board chosen for this work includes a variety of component sizes and types (Figure 1).

The components tested are as follows: 0402, 0603, 0805, and 1206 Imperial chip components (1005, 1608, 2012, 3216 metric); PLCC; SOT, and SOIC lead-frame components.

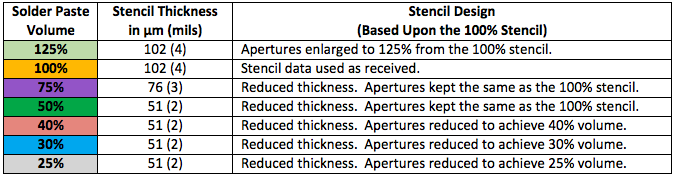

In an effort to determine the lower limit of acceptable solder paste volume, printed volumes were varied between 25 and 125% of nominal (Table 1).

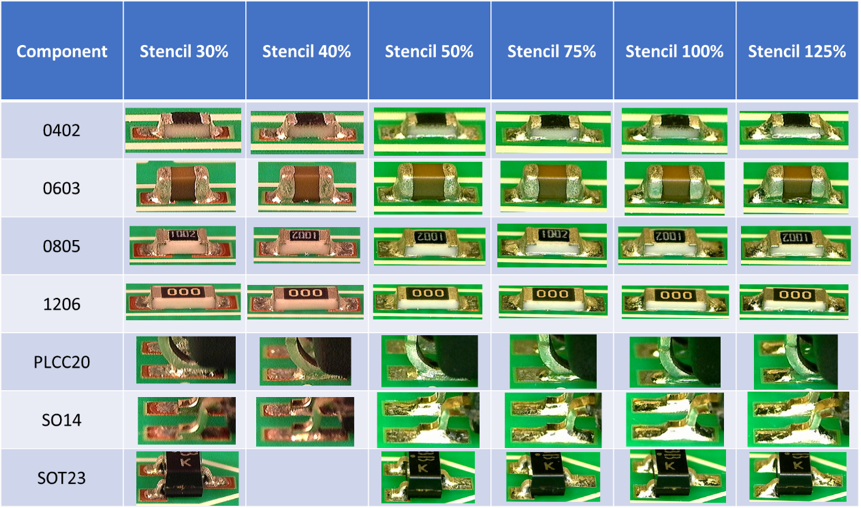

Solder joint quality was assessed using IPC-A-610 standard methods and cross-sectional analysis (Figure 2). Solder joint strength was measured using shear and pull tests. Thermal cycling between -40 °C and 125 °C was done for 1000 cycles and solder joint quality and strength was measured again.

In summary, the solder joint reliability data was correlated to printed solder paste volume. This was done in an effort to establish basic guidelines for the printed solder paste volumes required to generate reliable solder joints. This work will be will be presented at a technical conference. Please contact us if you would like more information.