Solder Materials for Automotive Markets

During automotive assembly, reliability is one of the most important goals for any manufacturer. Components and electronics need to withstand harsh environments including extremely high temperatures, extremely low temperatures, vibrations, and shock. There is a wide range of different requirements for every vehicle, from low weight, low cost in-cabin electronics, to underhood controls that must perform in any condition.

Process Solutions for Automotive Markets

Underhood Thermal Stress | In-Cabin Electronics | Minimize Voiding

Under the Hood Applications

Withstand extreme temperatures with LF-C2 Alloy

Underhood ECU’s | Braking Electronics | Steering Electronics | Exterior Lighting Controls | more….

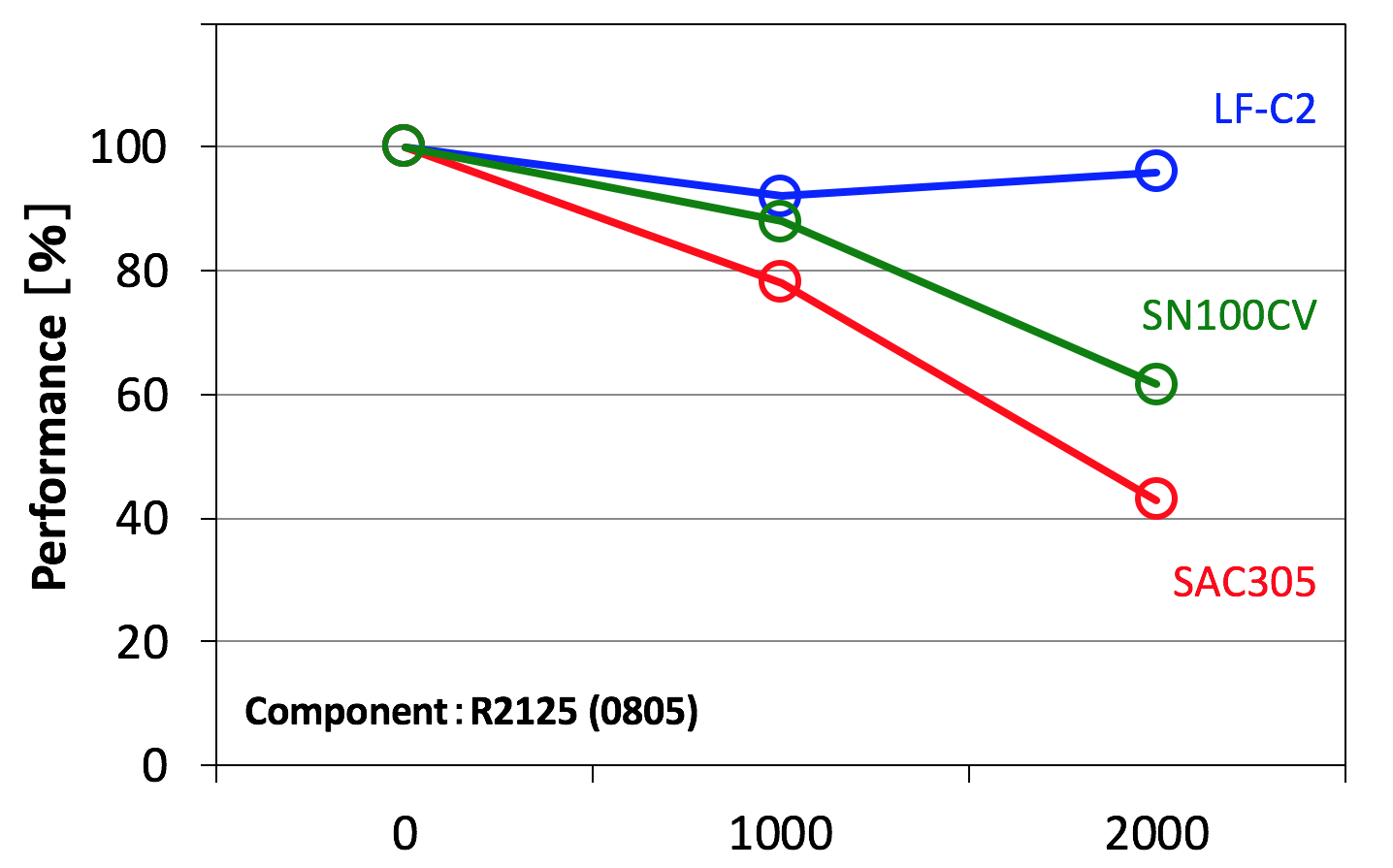

Thermal stress and thermal cycling are important factors to consider when assembling electronics that are subject to harsh environments. Under the hood and around the engine bay are areas within automobiles that require high-reliability electronics and controls. Therefore, building these electronics requires a high-reliability alloy such as LF-C2.

FCT Solder’s LF-C2™ alloy offers higher reliability than SAC 305/387/405

FCT Solder’s LF-C2™ alloy is typically used for underhood applications that have high operating temperatures because of its creep resistant properties.

During the product life cycle, thermal cycling weakens solder joints, leading to vibration and shock issues. LF-C2 alloy’s strength creates high integrity solder joints that perform during harsh conditions. Traditional alloys such as SAC often don’t provide the reliability needed for high-stress applications while current high-reliability alloys are often plagued by voiding issues.

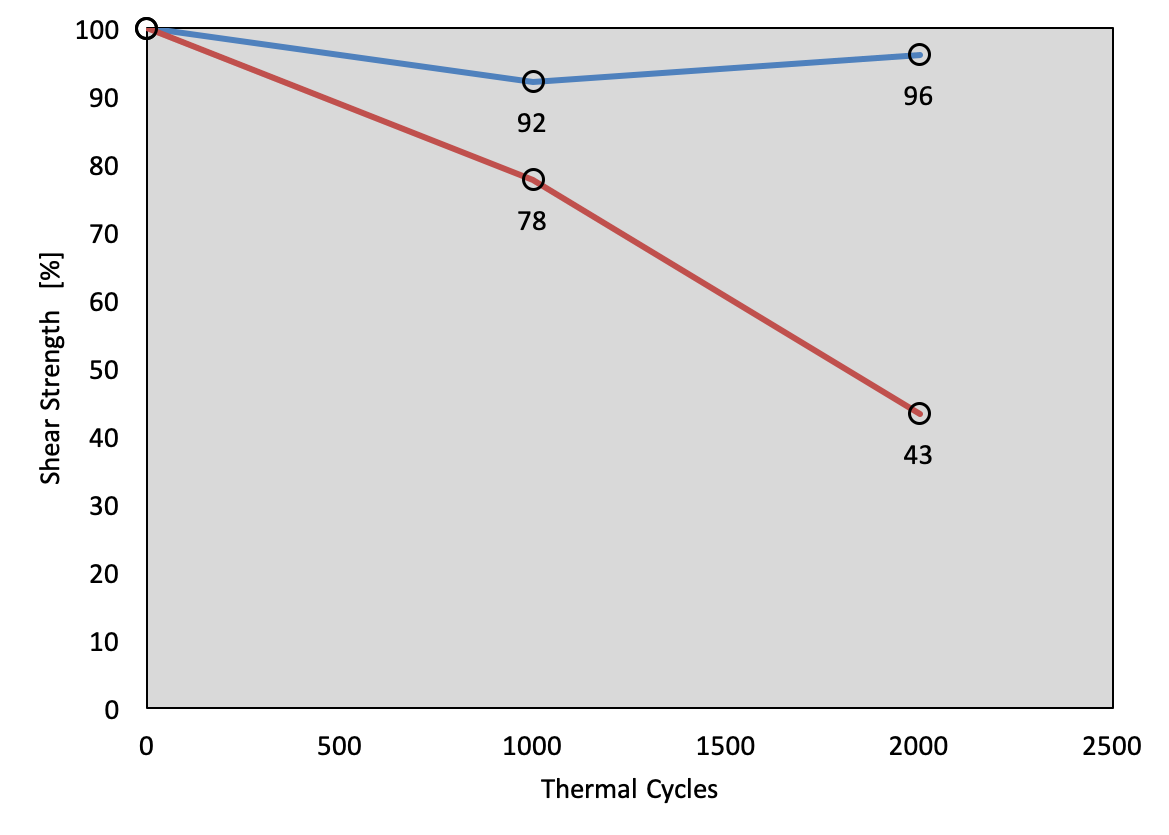

Below is a shear strength comparison between LF-C2 and SAC alloys during extended thermal cycling:

Shear Strength Comparison

Blue: LF-C2 | Red: SAC305

Component: R2125

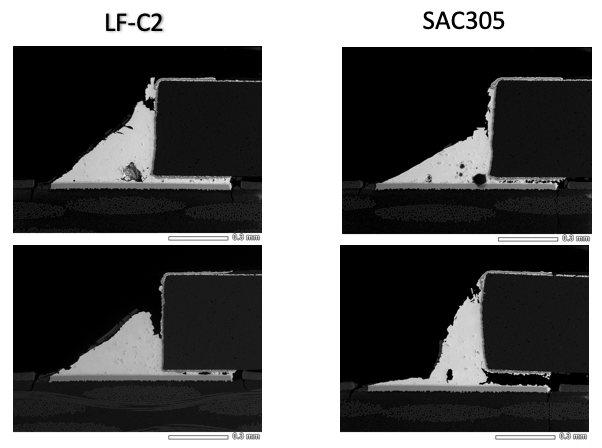

Cross Section after 2000 Thermal Cycles

Component: R2125

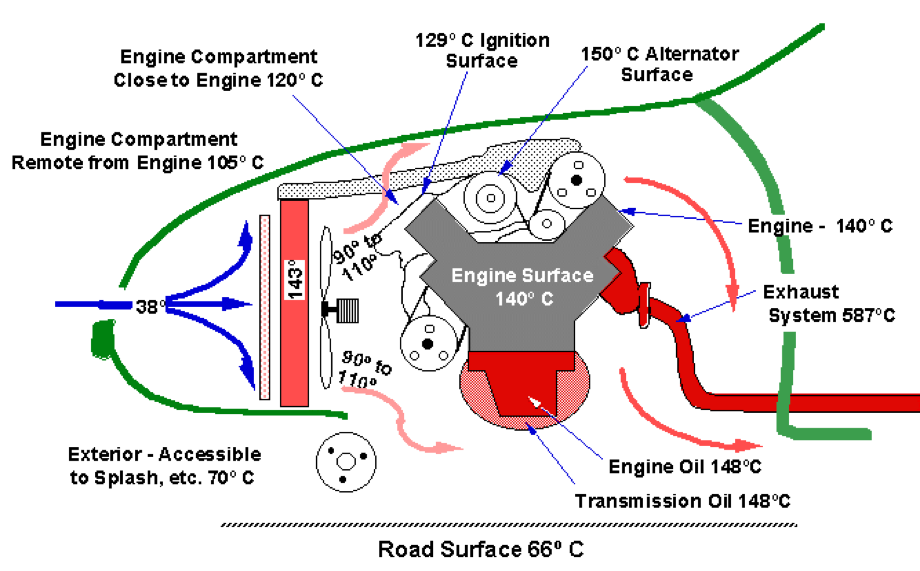

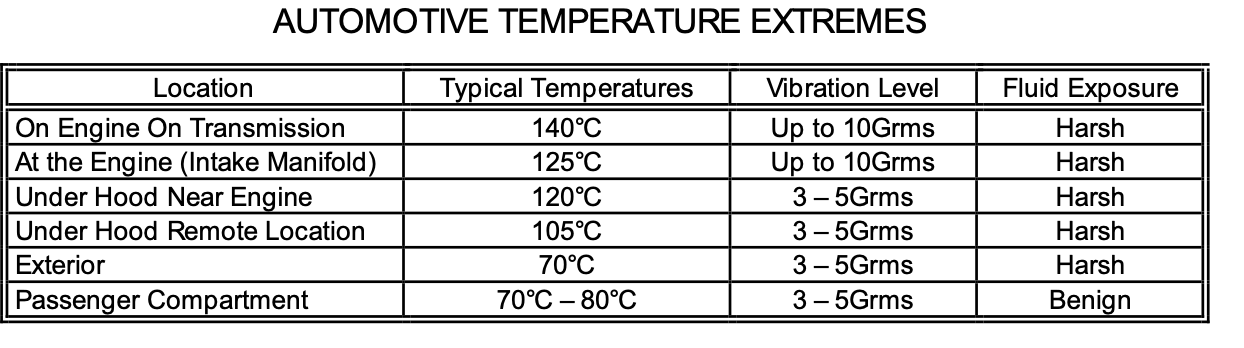

The chart on the right illustrates automotive temperature extremes.

The locations that have SAC alloy capability are:

- Underhood remote location

- Exterior

- Passenger compartment

Although, the locations that are beyond SAC capability are:

- On engine and transmission

- Intake manifold

- Underhood near engine

So for these harsh areas, use LF-C2 Alloy to ensure high-reliability solder joints.

Our LF-C2 Alloy and other solder materials are designed to perform in automotive assemblies- we combine ultra-low-voiding properties with high strength alloys suitable for extreme and harsh conditions.

In-Cabin Applications

LOWER ASSEMBLY COST WITH SN100CV ALLOY

Instrumentation | Power Distribution | Seat Electronics | Interior Lighting | Audio/Infotainment | more…

Are you looking for a lower-cost alternative to SAC305 with enhanced reliability? Our SN100CV alloy is an excellent choice. It offers more stable reliability and is around 30% less expensive than SAC alloys.

The SN100CV alloy is a great choice for low cost and high reliability. It’s an Ag-free solder alloy designed to meet the high performance requirements of products that need higher long-term reliability than SAC305, which tends to lose reliability with increased temperature ranges and dwell time.

While SAC305 has long been a favorite lead-free alloy in the industry, our SN100CV alloy offers more stable reliability at a lower cost than silver alloys. For example, in shear tests, SAC305 shows much faster deterioration than SN100CV. It also shows significantly more cycles to failure in testing.

Shear Test Results

SAC305 shows much faster deterioration.

FCT Solder offers both SN100CV and SAC305 solder alloys to help manufacturers in a variety of industries meet the unique demands of their project requirements, but in general, we’ve found SN100CV to be a great choice for the needs of the automotive industry, especially for in-cabin electronics.

SN100CV’s formulation addresses one of the biggest failings of SAC alloys, which is that the strengthening properties imparted by silver can be temporary. SN100CV possesses more stable, sustainable strengthening effects, but the process temperatures can still match those of SAC305.

SN100CV is an excellent choice for most high-reliability applications, including in-cabin and electric vehicle electronics. It boasts microstructural stability and offers a balance between strength and compliance.

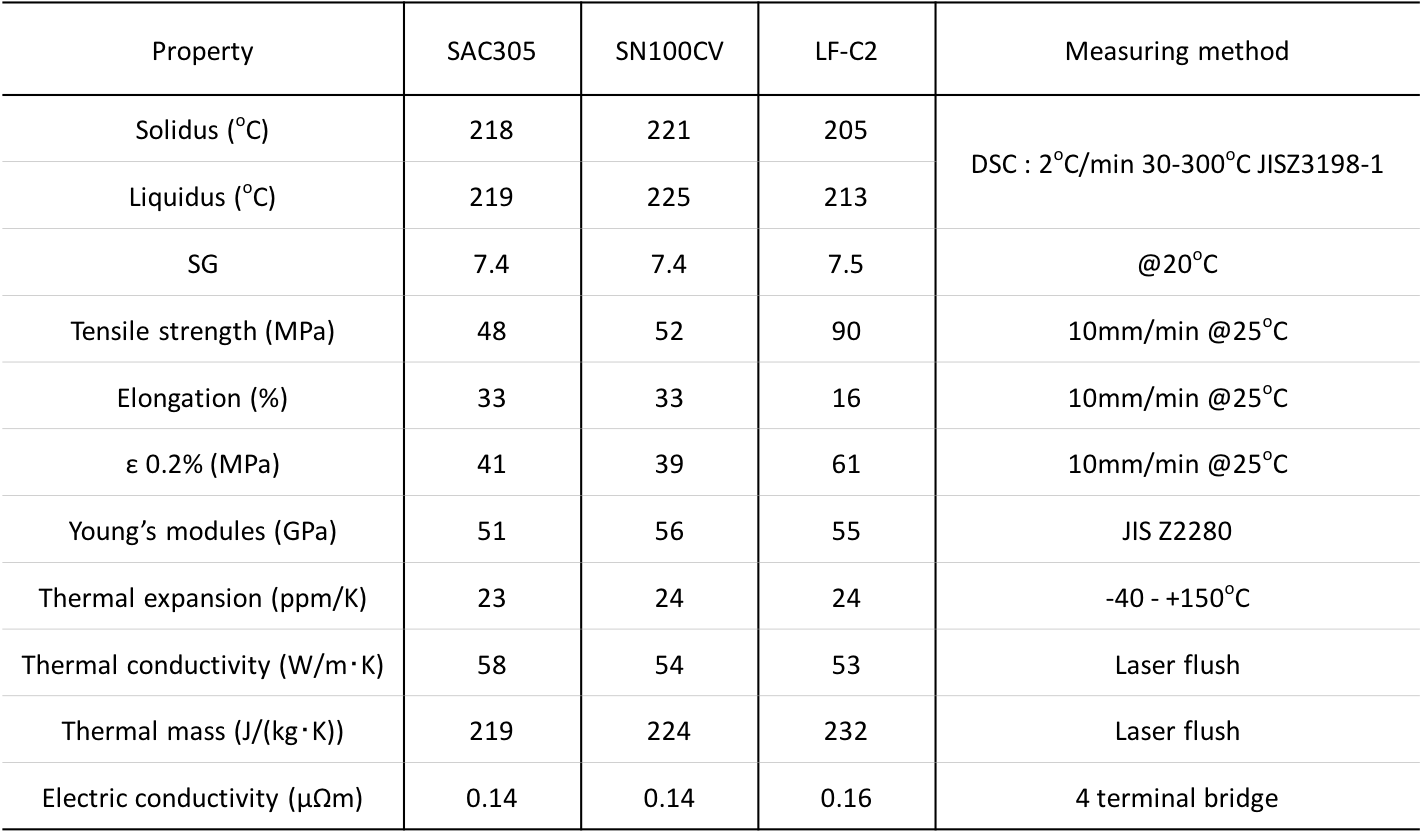

General Properties

That’s why we’ve developed a low-temperature solder paste to help protect semiconductors from high heat required to use solder. Low processing temperatures allows for the use of lower weight flex circuits and laminates. Thermal stress can be best managed by using NC722 Sn/Bi58 solder paste which has a melting point of 138-140C. This is a great paste for low-temperature assemblies inside the cabin.

SN100CV alloy for low cost and high reliability.

NC722 low temp paste for better economy.

NC722

Flux Type: No Clean

Alloys: Low melting lead free, tin bismuth alloys

Classification: ROL0

Halogen: Zero

Prevent Voiding

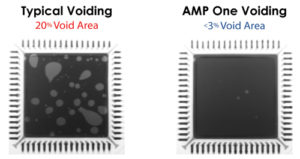

Voiding is a challenge in automotive manufacturing because it can weaken the joints, which are already under tremendous stress from shocks, vibrations, and extreme temperatures.

Recommended products to reduce voiding:

While all of our products are created to minimize voiding, this issue can be minimized using our AMP One solder paste.

AMP One is redefining the voiding standard for PCB Assembly by combining industry-low levels of voiding performance with excellent activity. When you need long-lasting reliability, rely on Amp One to deliver.

AMP One also gives automotive assemblers the benefit of low solder balling and graping, making it a great choice for under-the-hood applications where reliability in harsh environments is key.

Why FCT Solder for Automotive Applications?

We take a solution-driven approach to every product we develop. We’re intimately familiar with the defects that automotive manufacturers face, from voiding to thermal cycling and more.

FCT Solder’s solder paste and flux technology are all designed to reduce common problems in automotive manufacturing and are thoroughly tested for high performance and reliability. Our low-temperature solder paste help your products meet quality standards, and we provide a wide variety of solutions for your needs.

Materials You Can Rely On

When you order from FCT Solder, you know you’re getting:

- Low-graping products, with both water-soluble and no-clean options.

- Zero-halogen and zero-halide options with good activity and stability.