Solder Materials for IT and Telecom Markets

FCT Solder creates solder products with the challenges faced by IT and telecom manufacturers in mind. We’re dedicated to helping you reduce issues and create high-quality products with durability and longevity.

Why FCT Solder for IT and Telecom Projects?

FCT Solder’s products are all designed to solve problems, from voiding to tombstoning and beyond. Our solder paste, bar, wire, and flux technology are have all been thoroughly tested to ensure excellent performance.

What Makes Our Solder Materials Better?

We focus on the things that matter for IT and telecom applications. When you need products that work for fine pitch, small aperture printing and minimize common defects, look at our line of process solutions.

We deliver:

- Low-graping products in both water-soluble and no-clean options.

- Zero-halogen and zero-halide products with good activity and stability.

Process Solutions for IT and Telecom Markets

Head-in-Pillow Defects

The head-in-pillow defect occurs sometimes during reflow and wave soldering due to issues such as poor wetting. The balls fail to coalesce with the solder on the pad, creating a defect that looks like a head on a pillow. It’s especially common when using ball grid arrays (BGAs). Warping can cause head-in-pillow issues in components on BGAs.

Recommended products for reducing head-in-pillow defects:

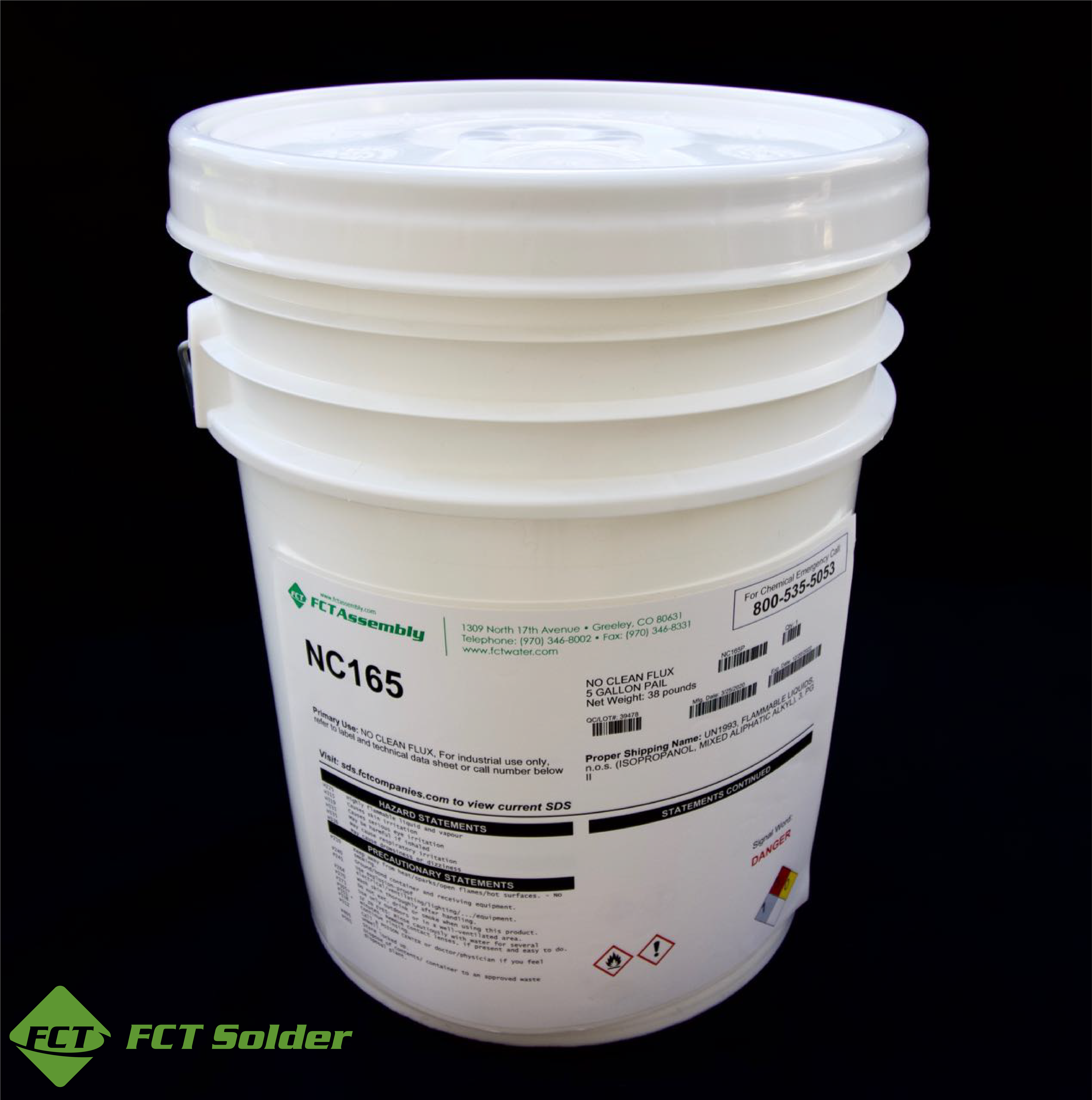

High activity water-soluble solder pastes like WS890 minimizes the potential for head-in-pillow defects, as well as for solder balling. No clean liquid fluxes, such as our NC165, protect the solder mask, too.

AMP One

The AMP One solder paste from FCT Solder, is redefining the voiding standard for PCB Assembly. By combining industry low levels of voiding performance with excellent activity and decreasing the potential for solder balling and graping, AMP One delivers assemblers an unmatched ability to amplify their process window while ultimately achieving higher yields.

Attributes:

-

Flux type: No Clean

-

Alloys: Lead Free

-

Classification: ROL0

-

Halogen: No

NC165

No-clean fluxes save time and money, but IT and telecom manufacture need to be sure that the no-clean flux residue will play well with conformal coatings.

Our NC165 flux leaves very little residue and is an excellent choice for most telecom applications.

Attributes:

- Halide free

- Very little residue

- Eliminates solder balling

- Low rosin content

WIL-1

FCTA WIL-1 is a VOC FREE low activity & solids, no-clean, wave soldering flux. It is designed to make the transition from tin-lead to lead-free wave soldering as efficient and profitable as possible. WIL-1 provides best in class productivity combining extremely high electrical reliability with excellent solderability, ultra-low residue and no white residues.

Attributes:

- Halogen free

- Pin testable

- Residues free post-process

- Wide Process Window

- Excellent Micro-Solderball Resistance

Long-Term Reliability

In IT and telecom operations, long-term reliability is crucial to avoiding costly repairs and field failures. Using the right solder materials is the key to products that hold up against time, environmental stressors, and gaining a reputation for reliable products.

Voiding

Voiding in solder joints is a huge headache, causing problems like mechanical weaknesses and thermal failure. If you can successfully eliminate voiding, you’ve scored a huge victory in the battle for durability.

Recommended Products to Reduce Voiding:

Our new Amp One ultra-low voiding solder paste is a no-clean, lead-free solder paste formulated with the specific goal of minimizing voiding. It’s leading the industry to new levels of performance.

Amp One is a good choice for assemblers who need:

- Low solder balling

- Zero- halide and zero-halogen formulation

- Excellent wetting to reduce common defects

- High activity

- Long stencil life