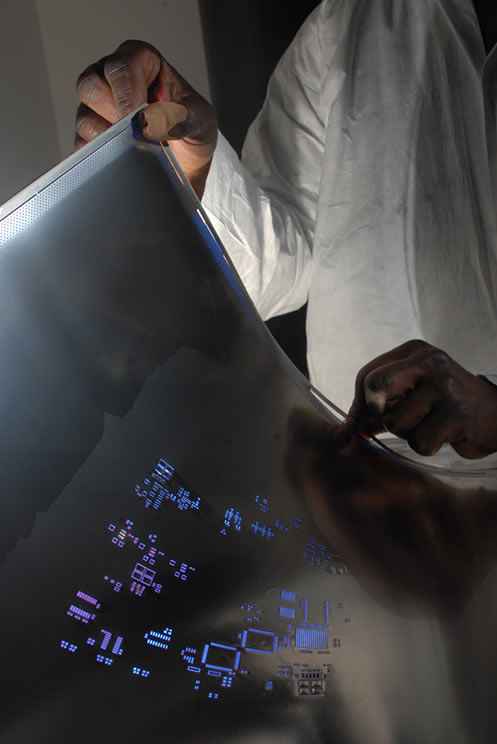

Electroform Stencil

FCTA Mexico manufactures electroformed nickel stencils to offer superior paste release as industry standard board designs demand smaller apertures and pitch. Electroformed stencil aperture walls are smooth (mirror-like), providing less surface area for solder paste to cling to. Instead of laser cutting apertures, nickel is formed around a photo resist template of apertures that matches board designs. Electroforming also allows quick turnaround times for jobs with large aperture counts.

ADVANTAGES OF ELECTROFORM STENCILS:

- Quick turnaround for jobs with large aperture count

- Smooth aperture walls, good paste release

- Electroform foil provides higher paste transfer efficiency than uncoated laser cut stencils

- Nickel formed foils that are laser cut offer better paste release than laser cut stainless foils

- Electroform stencils have higher tensile strength and hardness than stainless steel stencils

-

Electroformed foils can be produced in non-standard thicknesses

SPECIFICATIONS:

Foil Thickness:

Aperture Tolerance:

Thickness Tolerance Over Area:

Center to Center Aperture Tolerance:

Trapezoidal Aperture Walls:

1mil – 7mil

+/- 0.0003″

+/- 0.0004 over 10”

10×10″ area: within 0.001″ of original

16×16″: 0.0015″

20×20″: 0.002″

Taper is approx. 0.1 mils [0.0001″] per side per mil of foil thickness. (E.g.) 5 mils thick foil would have ~ 0.5 mils taper per side