Solder graping is the incomplete coalescence of solder powder into a solder joint. It’s called “graping” because it looks like a bunch of grapes.

What causes graping, and why is it a problem?

Graping has increasingly become a problem for manufacturers as lead-free pastes become standard, requiring higher reflow temperatures.

The trend towards smaller electronics also contributes to graping. That’s because smaller paste volumes lead to more oxidation, especially at the surface of the solder powder.

Because graping interferes with the formation of a good solder joint, we’re committed to minimizing graping through our products and recommendations.

How to prevent graping

Are you dealing with graping issues that affect your solder joints? We’ve put together some recommendations for strategies you can try.

1. Minimize oxidation

Optimize the reflow profile to do two things:

- Minimize solder powder oxidation.

- Maximize activity of the flux during reflow.

Shorten the soak time to reduce solder powder oxidation prior to reflow. This will also prevent premature loss of flux activity. (Additionally, if you increase the peak temperature, that will provide more heat for the solder powder to completely coalesce.)

2. Change the type of solder powder you’re using

Switching to Type 3 solder powder, rather than using Type 4 or 5, can be helpful. If your application allows for a swap, give it a try!

Type 3 solder powder has lower surface area (and correspondingly lower oxide) relative to Type 4 or 5 solder powders.

3. Switch to a higher-activity solder paste formulation

We supply higher-activity versions of many of our solder pastes for just this reason. The use of higher concentrations and different types of activators allows the paste flux to deal with high levels of oxide on solder powders.

NL932X and NL932PTX are higher-activity versions of NL932 and NL930PT respectively.

The AMP One solder paste combines industry low levels of voiding performance with excellent activity and decreases the potential for solder balling and graping.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

NL930PT is a zero halide, zero halogen, lead free, no clean solder paste that is pin probable. This paste delivers area ratio (AR) paste transfer efficiencies below 0.50.

Flux Type: No Clean

Alloys: Lead-Free

Classification: ROL0

Halogen: No

4. Modify the stencil to print a higher volume of paste in trouble spots.

Graping is typically seen on smaller pads, where there might not be a high enough volume of solder paste. Our NanoSlic stencil coating provides the benefit of increased solder paste volume, even through apertures down to 0.300 AR (area ratio).

Apertures can typically be enlarged for higher solder paste volume. Of course, this has to be weighed against the other demands of your design.

Engineering Support

Experiencing graping issues?

Give our engineers a call to talk things through and find a solution.

Resources to Help with Graping

Our team is dedicated to developing solder products that solve problems. Check out these resources for more insight into graping and other common solder issues.

Dispelling the Black Magic of Solder Paste

This paper outlines a way to quickly and inexpensively evaluate the solder paste you’re using for strengths and weaknesses, including graping.

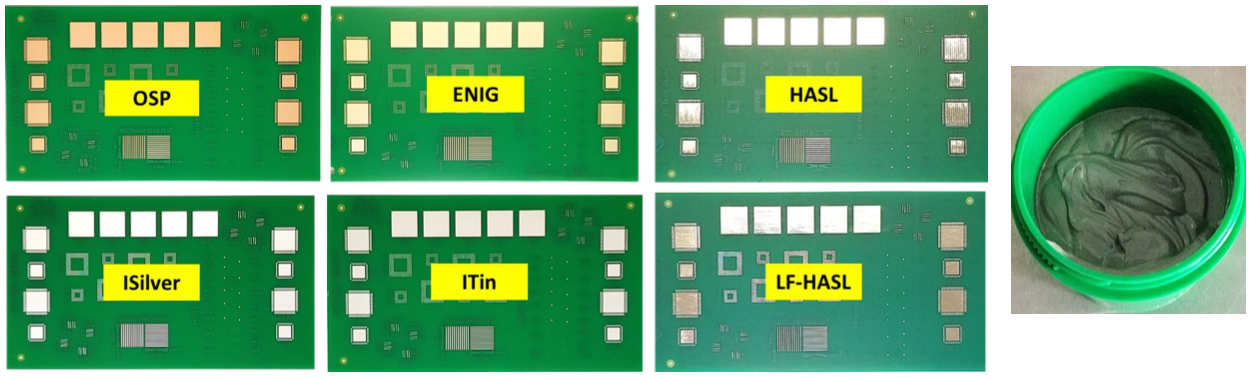

How Does Surface Finish Affect Solder Paste Performance?

The surface finish of printed circuit boards (PCBs) affects solder paste performance. This paper explores the effect of different surface finishes, including HASL and OSP, on solder paste performance.