Step Stencil Technology

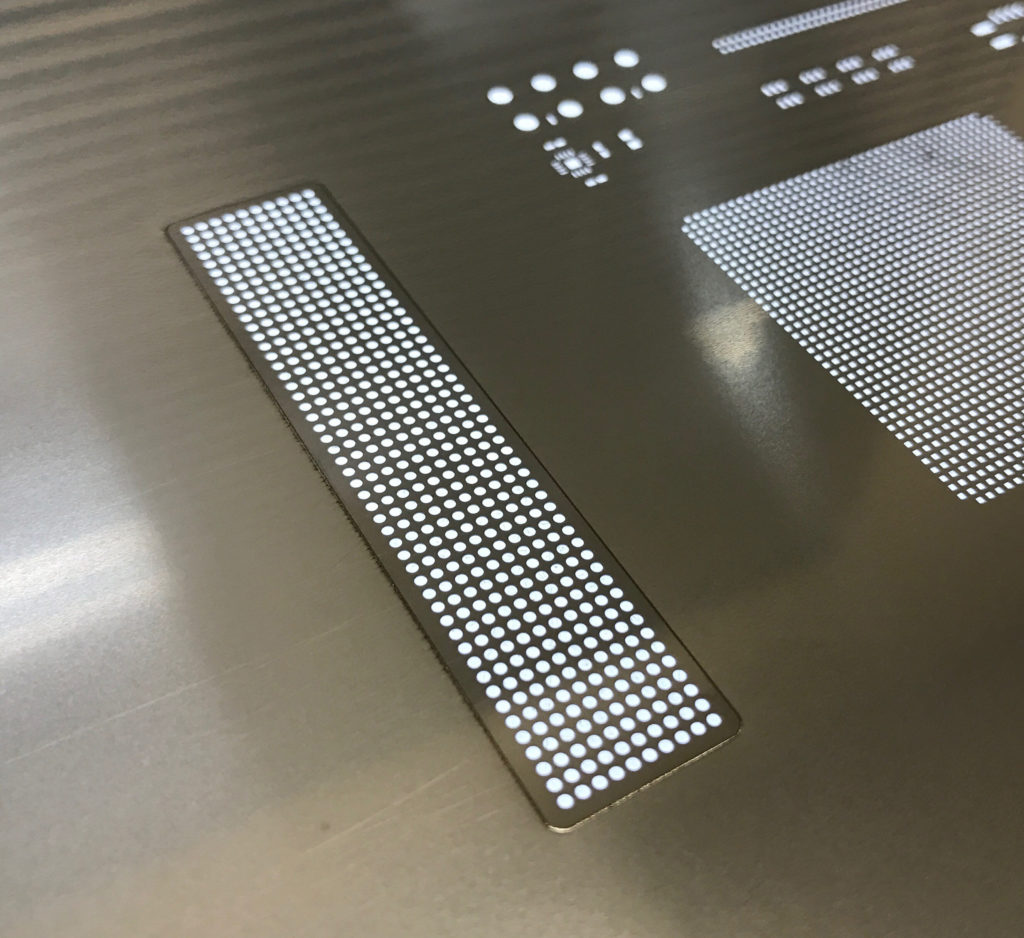

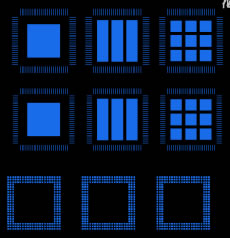

Multi-level (step) stencils from FCTA Mexico are designed and manufactured by using various techniques to improve stencil printing. Through the increase of mixed technologies, stepped stencils have gained importance to the electronic assembly manufacturer. If the solder paste quantity can no longer be adequately regulated by adjusting the pad sizes, stepped stencils are necessary to optimally match the soldering paste volumes.

Relief areas can be precisely milled or etched into the board side of the foil for use on rework boards. The higher reworked area fits into the relief allowing the stencil to lay flat on the SMT pads. This minimizes bridging by ensuring a gasket seal between the stencil and board pads. Damage to the board and stencil is also minimized. This is an excellent solution for boards with labels and boards with filled vias.

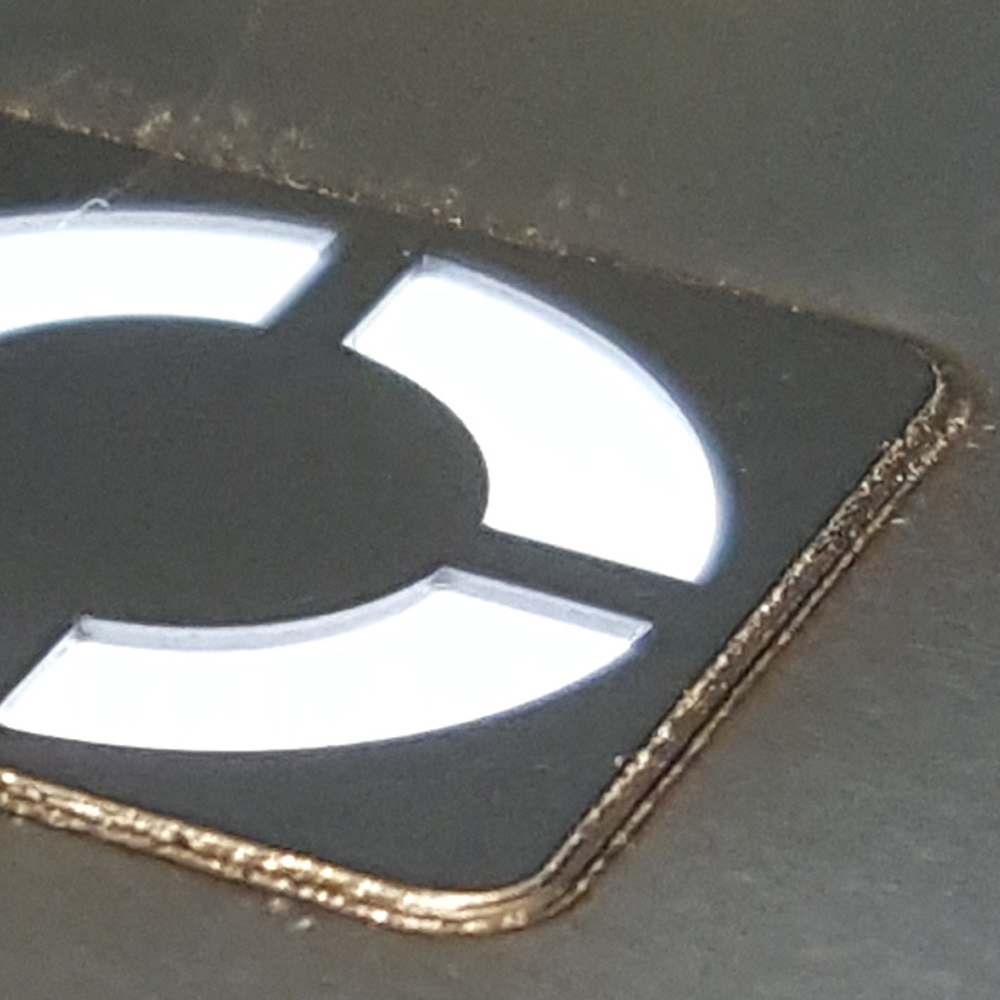

Step up areas are created using a patented laser weld process that ensures a smooth print with no squeegee damage. Different design and layout specifications have to be taken into account in the manufacture of stepped stencils. Please consult your FCTA Mexico customer representative for guidance on which technology is best for your process.

Papers

EVALUATING THE NEXT GENERATION OF STENCIL STEPPING TECHNOLOGIES

Component miniaturization isn’t just for phones anymore. The explosion of wearable and IoT connected electronics is accelerating the adoption of smaller packages in many markets, creating a “New Normal” for the SMT assembly industry. To capture and retain business, PCB assemblers can no longer wait for the more intricate processes to be proven out in mobile products and slowly work their way into the mainstream; instead they must proactively develop and demonstrate robust processes to print, place and reflow the emerging smaller components on the same boards as standard SMT components.

STEP STENCIL TECHNOLOGIES AND THEIR EFFECT ON THE SMT PRINTING PROCESS

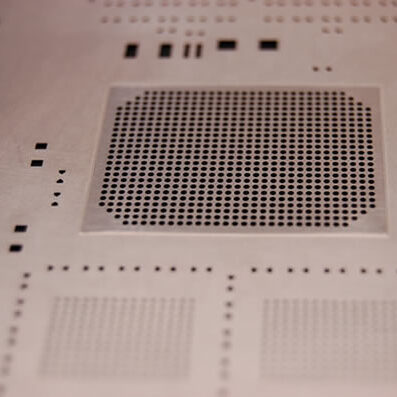

It is a common fact that the print process is one of the most critical elements in SMT production and many of today’s assemblies include both miniature components such as 0201’s, Micro-BGA’s, LGA’s and QFN’s as well as large components such as large connectors on the same assembly. Printing the proper volume of paste on these assemblies is not always possible by adjusting the apertures on single level stencils. As a result, manufacturers are finding that “Step Stencils” allow them to apply the correct amount of paste to different components on the same assembly with excellent first pass yields.